Variations on a calico glaze

firing to cone 10 in oxidation

slow downfire at 50 deg F an hour in the interval 1850 deg F to 1700 deg F

slow downfire at 25 deg F an hour in the interval 1700 deg F to 1650 deg F

One hour hold at 1650 deg F

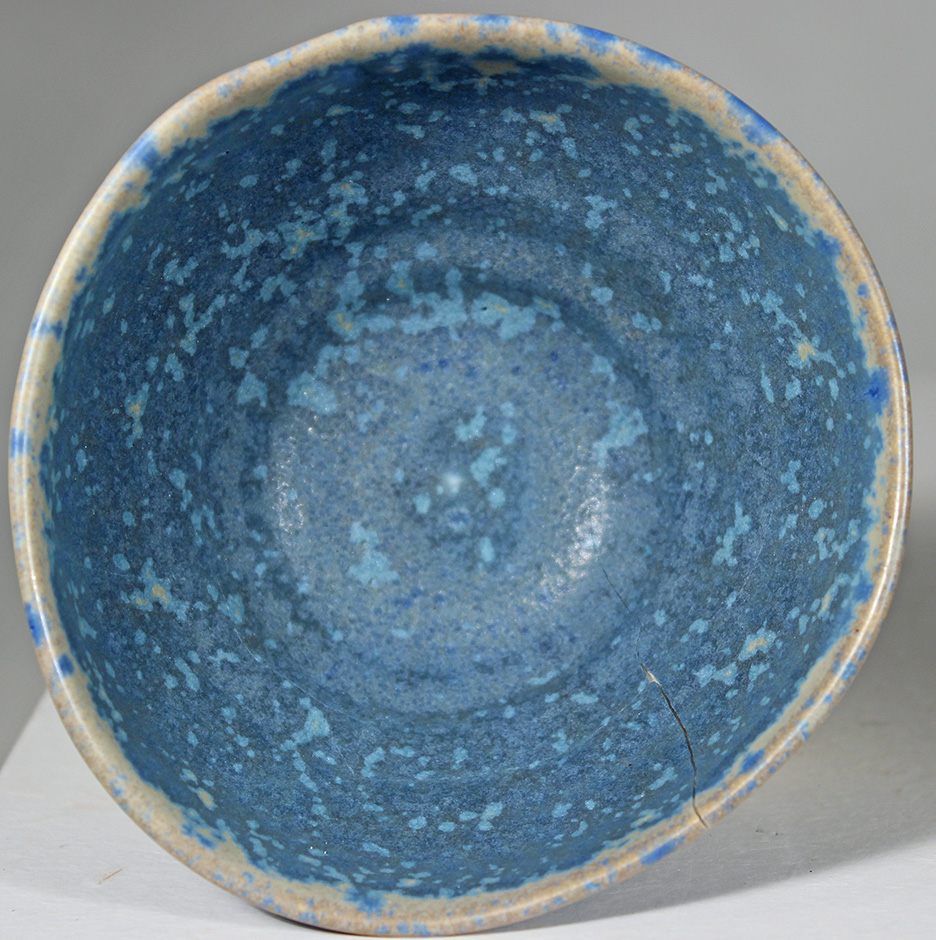

The first calico glaze

glaze cooper_404_1 bowl 3 inches in diameter

These glazes are minor variations of the above glaze, the ur glaze, the modifications are described with each glaze pair.

Variations on this glaze

glaze cooper_404_1Zn

Modifications are restricted to changes in the relative proportions of the bases (fluxes) in the seger formula of the 'ur' glaze.

Some BaO of the 'ur' glaze is replaced with ZnO.

The result is a glaze in which the orangy brown phase is gone. Additionally the pot has a large dunting crack.

glaze cooper_404_1Al

Modifications of the seger formula of this glaze are in alumina and silica, both of which are increased,

while the silica:alumina ratio of the ur glaze is preserved. The result is again the loss of the orangy brown phase.

glaze cooper_404_1Sr

Modifications are restricted to changes in the relative proportions of the bases (fluxes) in the seger formula of the 'ur' glaze.

Some BaO of the 'ur' glaze is replaced with SrO.

The result is the near dissapearance of the dark green/turquoise phase. There are several substantial dunting cracks in the pot.

glaze cooper_404_1PLi

Modifications are a change in the relative proportions of the alkali metals, and an increase in silica in the seger formula of the 'ur' glaze.

Some K2O is replaced with Li2O. The result is a decrease in the dominance of the dark turquoise phase.

The 'blobby' second phase features decrease in size with increased color variations. The texture of the glaze is smoothed to a silky matte.

glaze cooper_404_1Na

The seger formula is modified by a change in the balance of the alkali metals, some K2O is replaced by Na2O.

The result is an increase in the orangy brown phase.

glaze cooper_404_3

The bases (fluxes) of the seger formula are modified by an increase in BaO with a corresponding decrease in alkali metals.

To compensate for the expected decrease in fusibility of the glaze, K2O and Na2O are largely replace by Li2O.

The result is that the surface is smoothed to a silky texture.

Additionally, the colored regions are smaller and correspondingly there is more mixing together of the variously colored regions.