firing to cone 10 in oxidation

slow downfire at 50 deg F an hour in the interval 1850 deg F to 1700 deg F

slow downfire at 25 deg F an hour in the interval 1700 deg F to 1650 deg F

One hour hold at 1650 deg F

saturated iron glazes

All comparisons are of seger formula's of the relevant glazes

developing an oil spot glaze

|

|

|

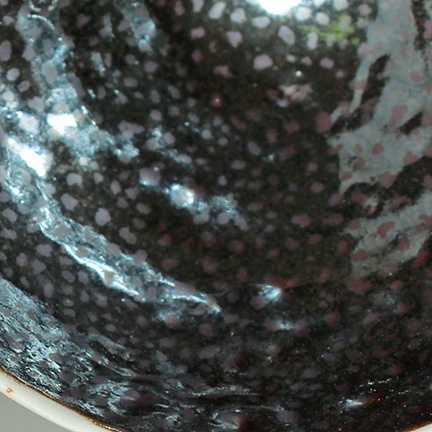

glazes mashikoKaki_3, mashikoKaki_3PLi, mashikoKaki_3PLiMSi

To show the progression in the development of the glaze, we observe closeups of the glazes.

mashikoKaki_3 migrates to mashiko_Kaki_3PLi via a shift of some KNaO to Li2O.

mashikoKaki_3Pli in turn migrates to mashikoKaki_3PLiMSi by a decrease in SiO2.

mashikoKaki_3 is underfired as shown by the strong dimpling of the surface.

the next, mashikoKaki_3PLi, is slightly less dimpled, but pitted where thick.

mashikoKaki_3PLiMSi is a mature oil spot glaze.

mashikoKaki_3PLiMSi with bubble

An additional interest in the test of mashikoKaki_3PLiMSi is the wash over the textured bit of shelf paper.

The picture doesn't well illustrate, the bubble which formed under this decoration.

I conjecture that as an oil spot glaze "blows bubbles" at the oil spots, the heavy application of wash

trapped beneath it the gasses which propel the iron to the surface, creating this bubble.

clay based glaze

|

|

glazes alberta_oil_0, alberta_oil_1

alberta_oil_0 is 66 % alberta slip, while alberta_oil_1 is 75 % alberta slip.

alberta_oil_0 migrates to alberta_oil_1 with a shift of 20% of its MgO to CaO and a slight increase in alumina and silica.

It would appear that the increase in CaO is more significant than the increase in Silica/alumina.

alberta_oil_1 with leaf print

crystals in a high alkaline glaze

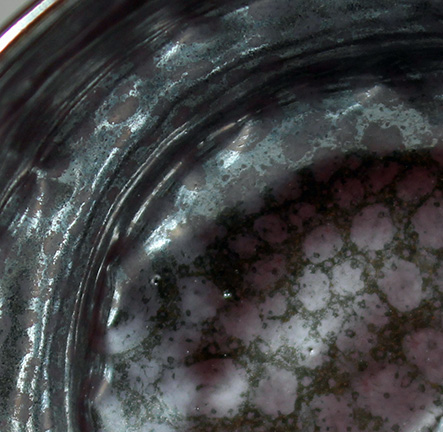

close up of glaze alk_179_1Cr

alk_179_1Cr is a low calcia high alkaline glaze containing titanium and chrome.

Note that there are both green and pink crystals visible.