Variations in a calico glaze

firing to cone 10 in oxidation

slow downfire at 50 deg F an hour in the interval 1850 deg F to 1700 deg F

slow downfire at 25 deg F an hour in the interval 1700 deg F to 1650 deg F

One hour hold at 1650 deg F

Here we show two calico glazes, and variations seen when fired and tested in distinct firings with the same firing profile, glaze composition and clay body.

These glazes show many colors and textures. glaze application thickness pot surface texture, as well micro details of the firing are the primary variables.

colors and markings, of these glazes are different every time. No telling what might show up. And yet, all the variations are interesting.

The two glazes displayed here are descendants of the cooper_404 glaze, though by now they have migrated substantially.

Both glazes have alumina a bit above .3, moderate akali metals and silica alumina ratio a bit above .7.

comparing the two glazes, cooper_404_1PLi and cooper_404_3, the first has higher alkali metals and lower baria than the second.

In compensation, the second has alkali metals nearly dominated by lithia.

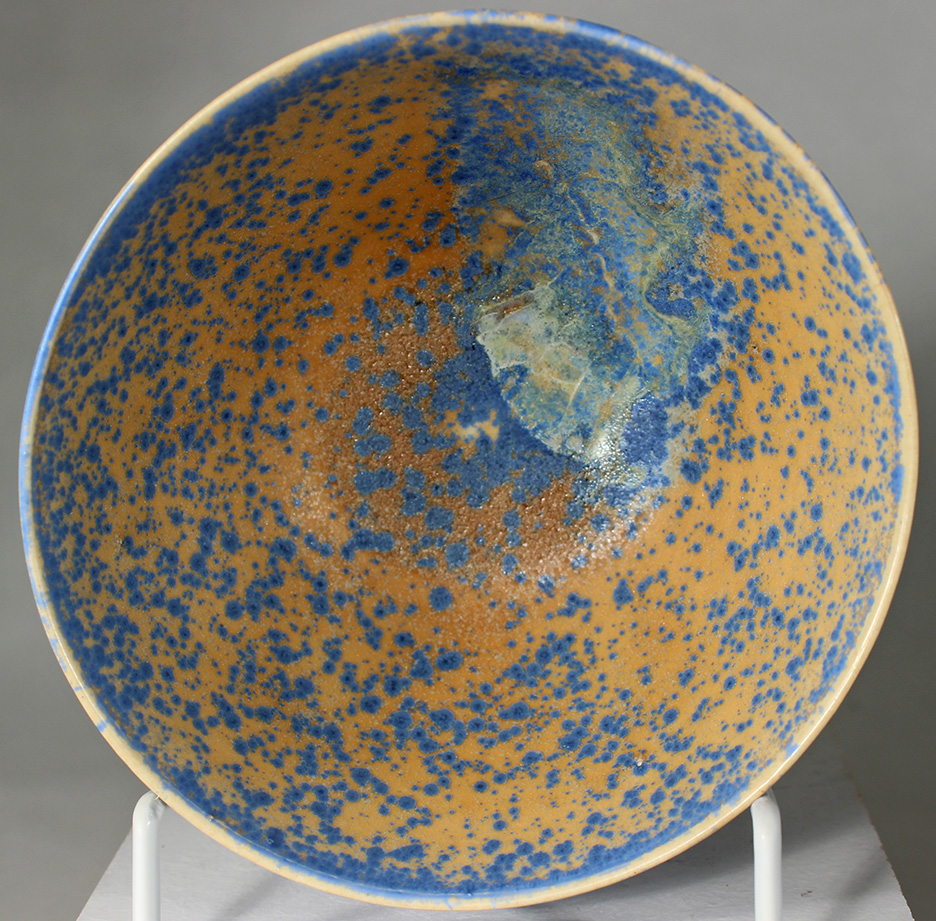

cooper_404_1PLi

We see its three faces on the inside of one bowl, then inside and outside of a different bowl.

bowl 3 inches in diameter

inside of bowl 5 inches in diameter

outside of above 5 inch diameter bowl

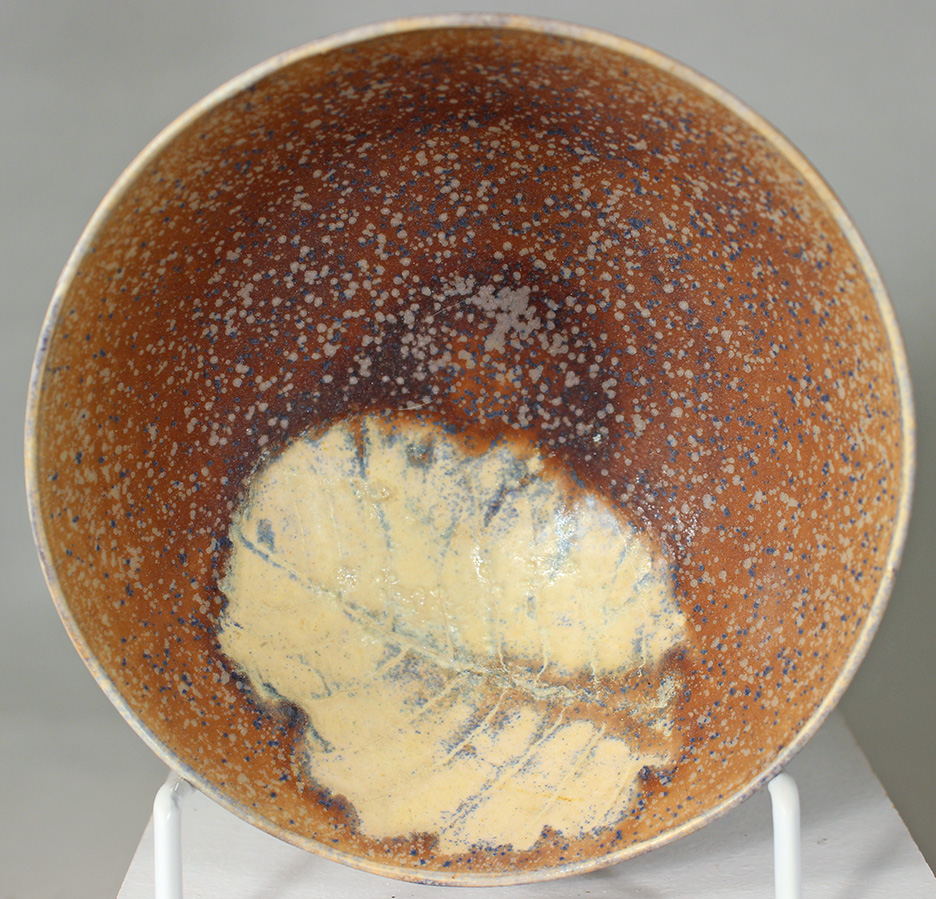

glaze cooper_404_3

We see its three faces on the inside of one bowl, then inside and outside of a different bowl.

bowl 3 inches in diameter

inside of bowl 5 inches in diameter

outside of above 5 inch diameter bowl