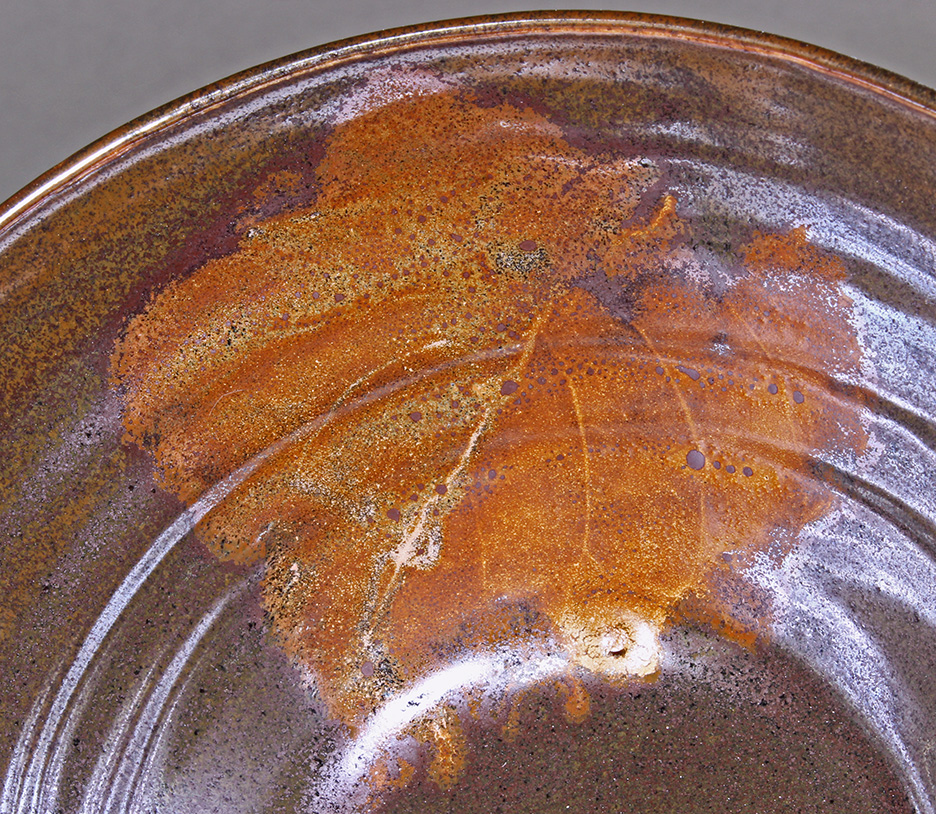

leaf prints on saturated iron glaze

firing to cone 10 in oxidation

slow downfire at 50 deg F an hour in the interval 1850 deg F to 1700 deg F

slow downfire at 25 deg F an hour in the interval 1700 deg F to 1650 deg F

One hour hold at 1650 deg F

iron glazes with sharp edged leaf prints

These leaf prints on saturated iron glazes show fine detail, sharp narrow veins and sharp leaf edges.

These and other details that had been missing in the impressionistic rather abstracted leaf prints I'd so far seen in iron glazes at cone 10.

The base glazes are a bit stiffer, and more, the leaf wash used to stain the leaf prints is less reactive with the base glaze.

These new washes don't move as much, or difuse into the base glaze as readily.

glaze composition

These glazes are high in alkaline metals, saturated iron glazes, with low calcia and moderate lithia.

Alumina in the emperical formula is between .5 and .6, the silica alumina ratio is between 5 and 6.

A low silica alumina ratio with low calcia and high alkali metals gives a moderately stiff full gloss glaze.

wash composition

There are two leaf washes used:

1. custer feldspar with rutile

2. EPK Kaolin with rutile

Half of each leaf is stained with each of the two washes.

The glaze iron_8_R_C10_11

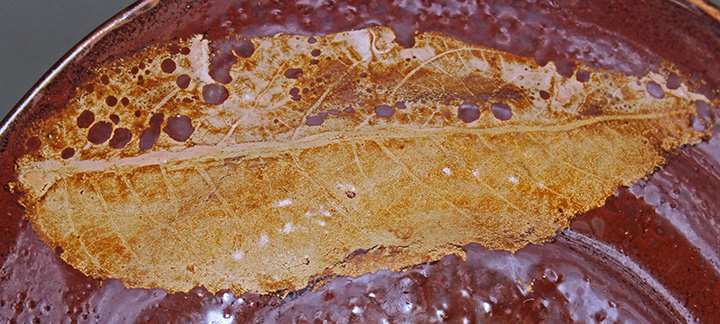

The glaze iron_Z14_0

This glaze was applied thick, and shows incompletely healed bubbles inside the bowl.

In order to see that the apparent underfired state is the result of an overly generous glaze application, we show the bottom of the bowl as well.

|

|

The glaze iron_Z14_1