cobalt breaking color

Glazes are fired at cone 6 in an electric kiln.

The kiln is cooled slowly, at a rate of 50 deg F an hour in the temperature interval 1850 to 1700.

It is then cooled 25 deg F an hour in the temperature interval 1700 deg F to 1650 deg F.

There is then a 1 hour hold at 1650 deg F.

The begining for these tests is:

glaze eqAlk_186_0 mug ~5 inches high

A beautiful glaze, which has dunted. As this glaze is high in lithium, five of the tests replace some lithium with an equivalent amount of a different basic oxide.

The bases present are K2O, Na2O , Li2O, CaO, MgO, SrO and ZnO.

In addition these glazes contain alumina, silica and 1 % cobalt carbonate.

Each glaze contains 1 % cobalt carbonate.

There is no added rutile in any of these glazes.

I now focus on minimal perturbations of base glaze.

The first five tests replace some Li2O with an equal molecular amout of one of Na2O, CaO, MgO, SrO or ZnO.

In addition there are two tests, which increase only Al2O3 or SiO2 with no other changes.

My intent is to make the most minimal changes possible with the hope of increasing understanding of the interactions of the oxides present in ceramic glazes.

The crawling which is seen in many of these glazes is entirely the result of mud crack pattern forming in the glaze slops while drying on the bisque ware, resulting from excessive ball clay in the glazes.

The crawling is at the location of the pre fired cracks.

The visible textural changes from base glaze are expected with a change in the chemistry and no compensatory change.

Variations on this glaze

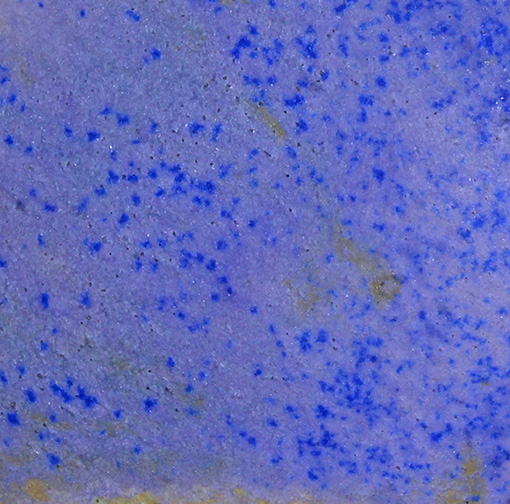

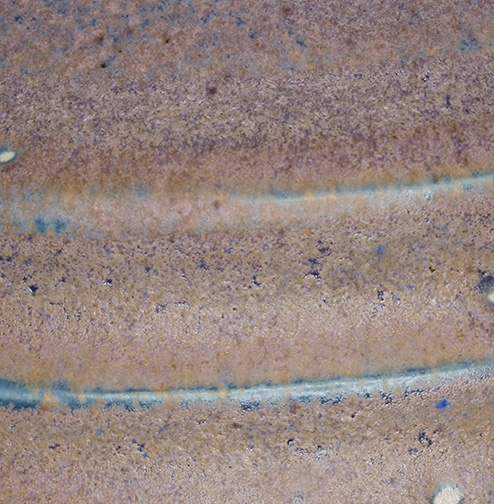

glaze eqAlk_4V_0

Some Li2O in base glaze is replace by Na2O.

Not surprisingly, as this represents a replacement of one alkali metal for a different one, this glaze shows the smallest shift in both color and texture from base glaze.

detail of the inside on the left, outside on the right.

|

|

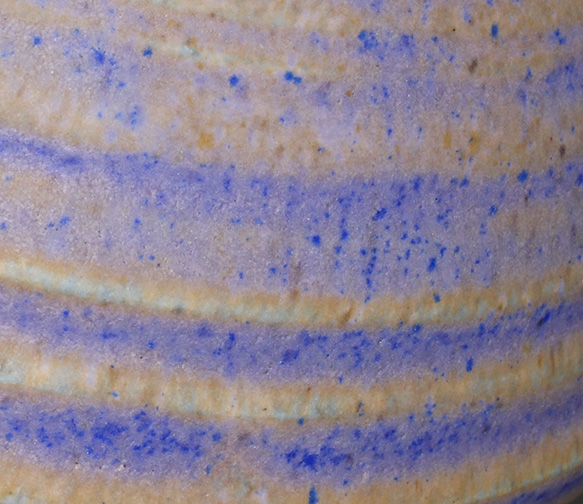

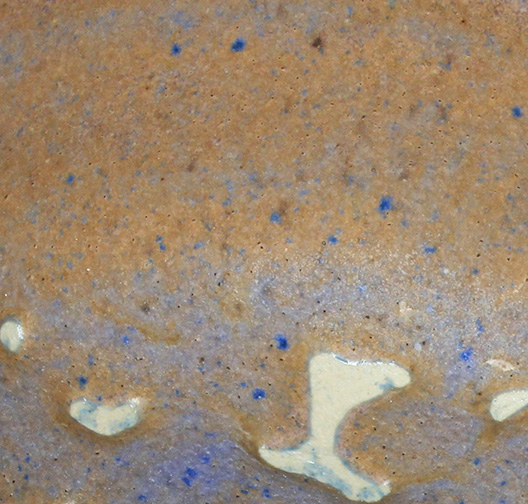

glaze eqAlk_4V_4

Some Li2O in base glaze is replace by ZnO. The result in a substantial change in color, with little shift in texture.

detail of the inside on the left, outside on the right.

|

|

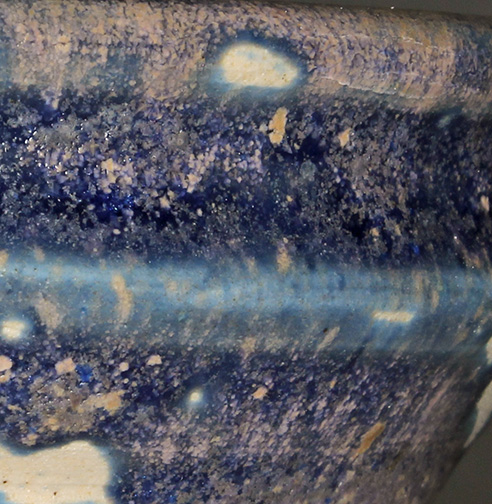

glaze eqAlk_4V_1

Some Li2O in base glaze is replace by CaO. The result in a substantial change in color, with an equally substantial shift in texture.

detail of the inside on the left, outside on the right.

|

|

glaze eqAlk_4V_2

Some Li2O in base glaze is replace by MgO. The result in a substantial change in color, with an equally substantial shift in texture.

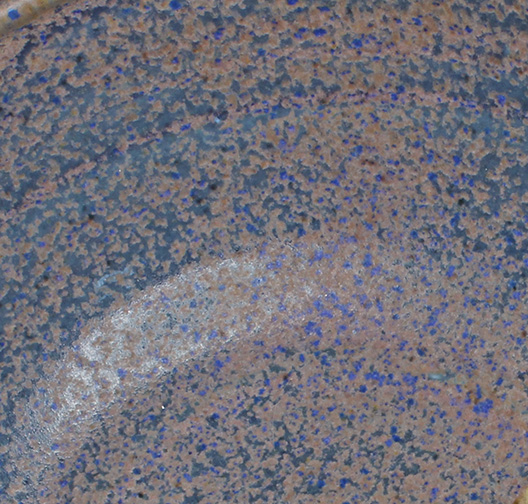

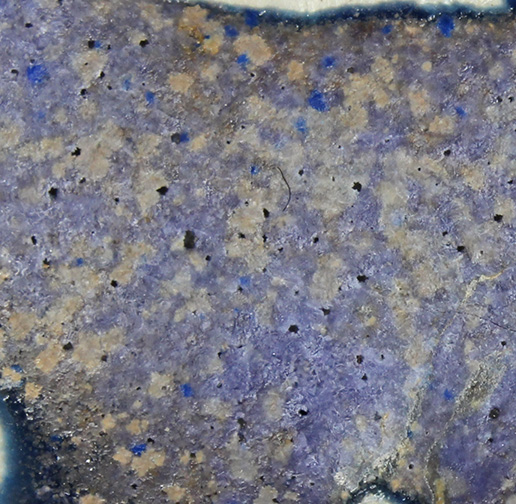

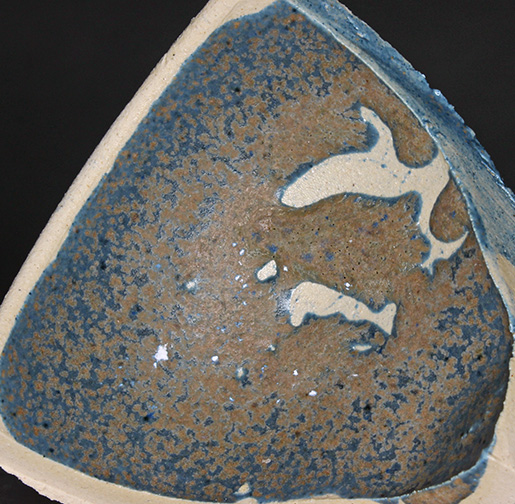

glaze eqAlk_4V_3

Some Li2O in base glaze is replace by SrO. The result in a substantial change in color, with an equally substantial shift in texture.

A bowl on the left, a detail showing the glaze breaking color on the right.

|

|

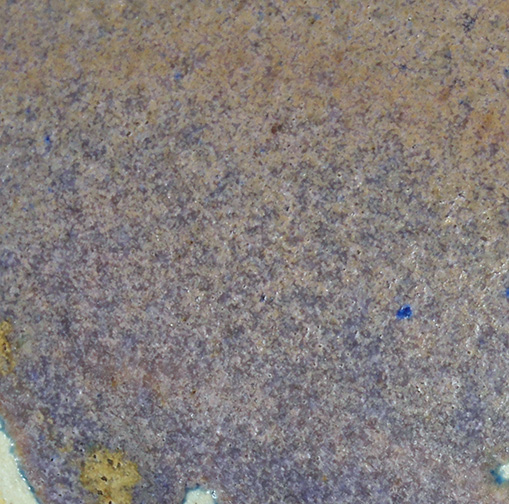

glazes eqAlk_4V_5 and eqAlk_4V_6

Both glazes eqAlk_4V_5 and eqAlk_4V_6 have the same bases in their empirical formulas as does base glaze.

eqAlk_4V_5 has a small amount of additional silica, eqAlk_4V_6 has some additional alumina.

The left, and middle image show a detail from eqAlk_4V_5, the right a detail from eqAlk_4V_6.

|

|

|