circa a saturated iron glaze

firing to cone 10 in oxidation

A half hour hold at 1850 deg F

slow downfire at 50 deg F an hour in the interval 1850 deg F to 1700 deg F

slow downfire at 25 deg F an hour in the interval 1700 deg F to 1650 deg F

One hour hold at 1650 deg F

circa a saturated iron glaze

I continue wandering in the land of glaze, near the glaze iron_8_Right_162_1Z_1 and its previously tested variants.

I modify a small number of components, so that one step at a time, I can examine the response to my modifications.

The glaze which is central to these investigations iron_8_Right_162_1Z_1, I call the alpha glaze:

The alpha glaze iron_8_Right_162_1Z_1

In each case I will describe the steps that lead from the alpha glaze to the last modification, and show images for the intermediate stages.

decrease both Alumina and silica |

increase both Alumina and Silica |

increase alkali metals |

decrease Alumina |

glaze composition

The alpha glaze

is high in alkaline metals and in Li2O, with Al2O3 = .5, SiO2 = 3.15 and P2O5

= .04.

The variants are all high in alkali metals and Li2O. Al2O3 varies

from .4 to .63, and Silica from 2.8 to 4. P2O5 remains .04.

decrease both alumina and silica

decreasing both alumina and silica, with constant silica

alumina ratio is an increase in the basic components of the glaze.

The relative proportions of the various bases is unchanged(i.e. fluxes).

The result is an iron red glaze with a dusting of metallic gold crystals.

The

lighter color, together with the decrease in the size of the crystal clusters

is consistent with the prior observation that the opposite change,

i.e. an

increase in alumina and silica giving a darker glaze with larger crystal

clusters.

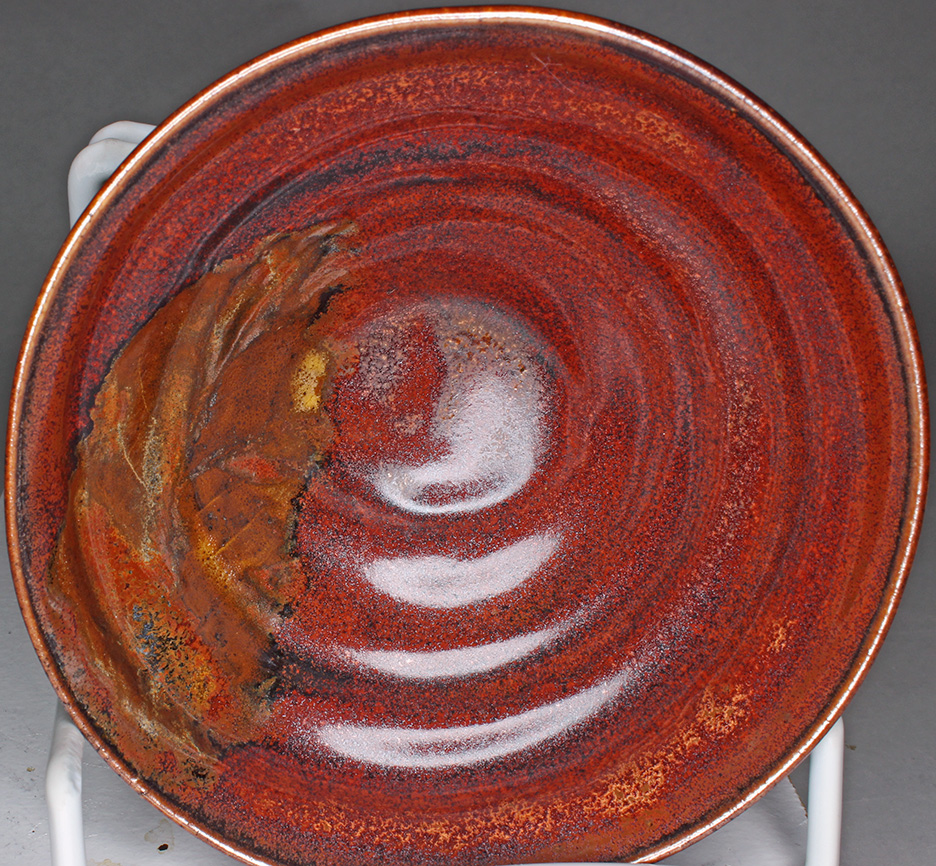

glaze satIron_ZG_H_1 bowl ~4 inches in diameter

increase alumina and silica

step 1. alpha glaze → satIron_ZG_4 |

increase both alumina and silica |

step 2. satIron_ZG_4 → satIron_ZG_H_4 |

increase both alumina and silica |

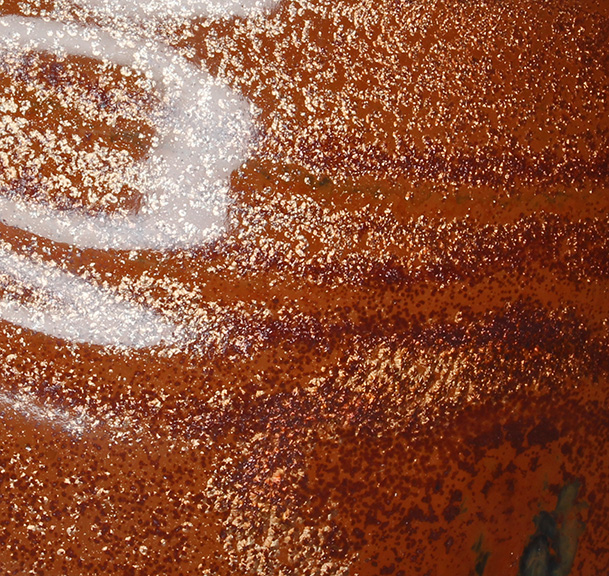

The image on top is a closeup of the glaze satIron_ZG_4, below is a picture of a small bowl glazed with satIron_ZG_H_4.

With the additional increase in both alumina and silica, the shift to a darker ground color in the glaze, and smaller metallic crystal clusters is evident.

|

|

increase alkali metals

step 1. alpha glaze → satIron_ZG_4 |

increase both alumina and silica |

step 2. satIron_ZG_4 → satIron_ZG_H_4 |

increase both alumina and silica |

step 3. satIron_ZG_4 → satIron_ZG_H_5 |

increase alkali metals (decrease alkaline earths) |

This glaze is derived from the above by replacing some of the alkaline earth bases by alkali metals. We show this one additional glaze.

glaze satIron_ZG_H_5 bowl ~4 inches in diameter

We see an increase in the density of the gold metallic crystals.

decrease Alumina

step 1. alpha glaze → satIron_ZG_1 |

decrease Alumina |

step 2. satIron_ZG_1 → satIron_ZG_H_3 |

decrease Alumina |

The top image is a close up of glaze satIron_ZG_1, below is a picture of a small bowl with satIron_ZG_H_3.

The shift in color, and fewer larger crystal clusters is more apparent in the second decrease in alumina.

|

|