Firing Saturated Iron Glazes

cone 10 oxidation with distinct downfire protocols

Firing #1 With slow downfire in two intervals

A half hour hold at 1850 deg F

slow downfire at 50 deg F an hour in the interval 1850 deg F to 1700 deg F

slow downfire at 25 deg F an hour in the interval 1700 deg F to 1650 deg F

One hour hold at 1650 deg F

Firing #2 With a long hold at 1800 deg F

half hour hold at 1850 deg F

A three hour hold at 1800 deg F

half hour hold at 1650 deg F

The slow downramp from 1850 Deg F of the first firing is replaced in the second firing by a 3 hour hold at 1800 Deg F.

Clay body is a grolleg porcelain from Tacoma Clay Art Center.

glaze composition

This glazes have high alkali metal, the numbers in the Empirical or Seger Formula:

Alkali metal .73

Li2O .17

Alumina .46

molecular % silica 63

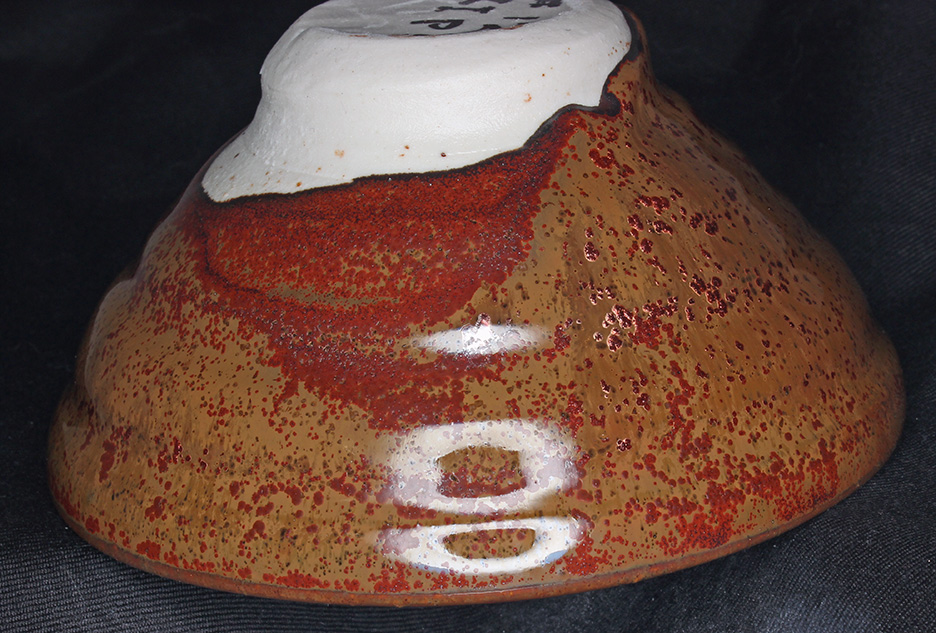

The pots are small conical bowls ~3 inches in diameter.

glaze iron_8_R_162_3Z_1 in Firing #1 with slow downramp

glaze iron_8_R_162_3Z_1 in Firing #2 with 3 hr hold at 1800 deg F

note red color

note glaze spill on foot

Note that the glaze has migrated from a waxy rather textured not quite full gloss in the first firing, to a sparkling gloss in the second firing. Note the substantial glaze spill onto the shelf in the second firing.