Firing Saturated Iron Glazes

cone 10 oxidation with distinct downfire protocols

I show the results of firing two saturated iron glazes in 6 different

firings.

Glazes which have prominent metallic crystals if fired with a slow downfire,

didn't exhibit those crystals with the downfire replaced by a 3 hour soak at

1850 deg F.

I then moved the temperature of that long soak down by 50 deg, and got

some crystals, and moving it further down got a few more.

Eventually I

fired those glazes with no holds or soaks above 1750 to get lots of metallic

crystals.

With the soak at 1850 in addition to the long soak and hold

at 1700 deg F the crystals are present.

I have not as yet found a

firing with only long holds that reproduces the first firing with the

long slow downfire.

I concluded that the metallic crystals visible in these glazes grow at a temperature below 1800 deg F, and likely closer to 1750 deg F.

Below are the firing profiles, and pictures of the glazes in each firing.

Firing #1 With slow downfire in two intervals

A half hour hold at 1850 deg F

slow downfire at 50 deg F an hour in the interval 1850 deg F to 1700 deg F

slow downfire at 25 deg F an hour in the interval 1700 deg F to 1650 deg F

half hour hold at 1650 deg F

Firing #2 With a long hold at 1850 deg F

A three hour hold at 1850 deg F

hour hold at 1650 deg F

Firing #3 With a long hold at 1800 deg F

half hour hold at 1850 deg F

A three hour hold at 1800 deg F

half hour hold at 1650 deg F

Firing #4 With a long hold at 1750 deg F

half hour hold at 1850 deg F

A three hour hold at 1750 deg F

half hour hold at 1650 deg F

Firing #5 With a long hold at 1850 deg F and at 1750 deg F

A three hour hold at 1850 deg F

A three hour hold at 1750 deg F

half hour hold at 1650 deg F

Firing #6 With a long hold at 1700 deg F

half hour hold at 1750 deg F

A three hour hold at 1700 deg F

slow downfire at 25 deg F an hour in the interval 1700 deg F to 1650 deg F

hour hold at 1650 deg F

Clay Body

grolleg porcelain from Tacoma Clay Art Center.

glaze composition

These glazes have high alkali metal.the numbers in the Empirical or Seger Formula for the two glazes are respectively:

Alkali metal .78

Li2O .2

Alumina .6

molecular % silica 63

Alkali metal .81

Li2O .2

Alumina .66

molecular % silica 63

The pots are small conical bowls ~3 inches in diameter.

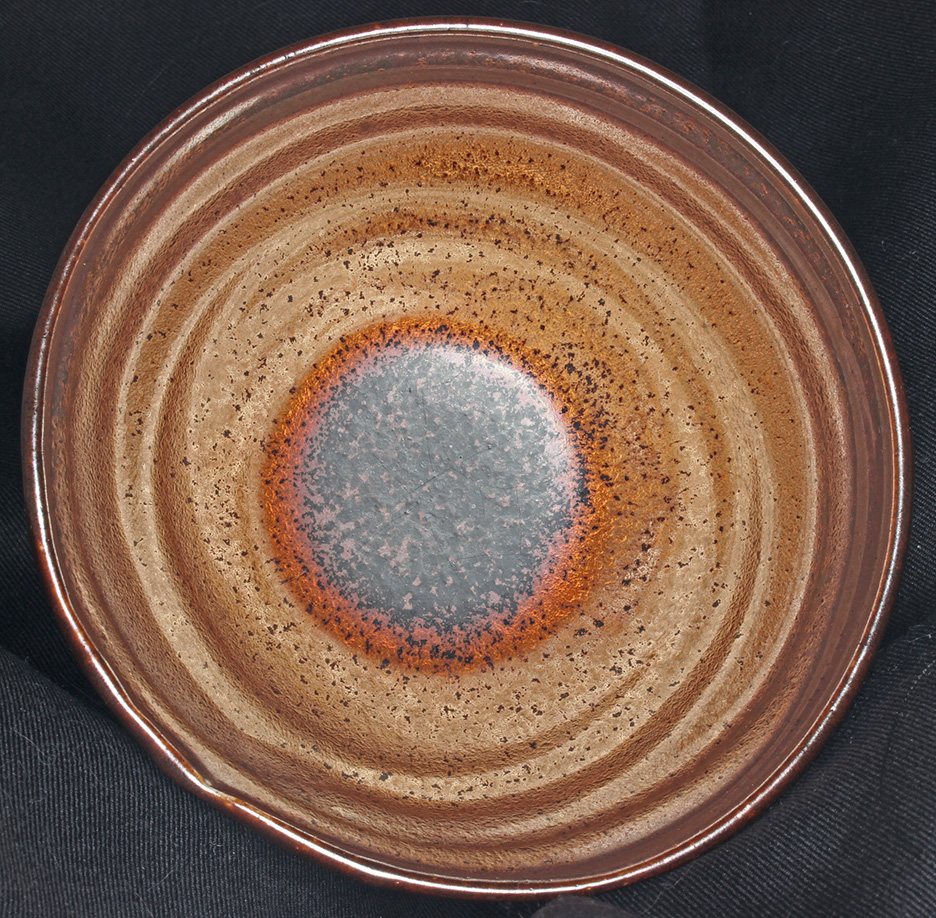

glaze satIron_ZG_0 in firings #1 through #6

|

|

|

|

|

|

glaze satIron_ZG_H_2 in firings #1 through #6

|

|

|

|

|

|