Crystals in high Lithium Iron Glaze

Glazes are fired at cone 6 in an electric kiln

Firing profile

A half hour hold at 1850 deg F

downfire at 50 deg F an hour in the interval 1850 deg F to 1700 deg F

downfire at 25 deg F an hour in the interval 1700 deg F to 1650 deg F

A one hour hold at 1650 deg F

Clay body is a B-mix variant from Tacoma Clay Art Center.

glaze composition

satIron_4Z_1

In the empirical formula:

alkali metals .75 with Li2O .36

alkali earths more CaO than MgO

alumina .42

Silica 3.3

P2O5 .05

The pot is a cylinder ~3.5 inches in diameter,

glaze satIron_4Z_1

the pot

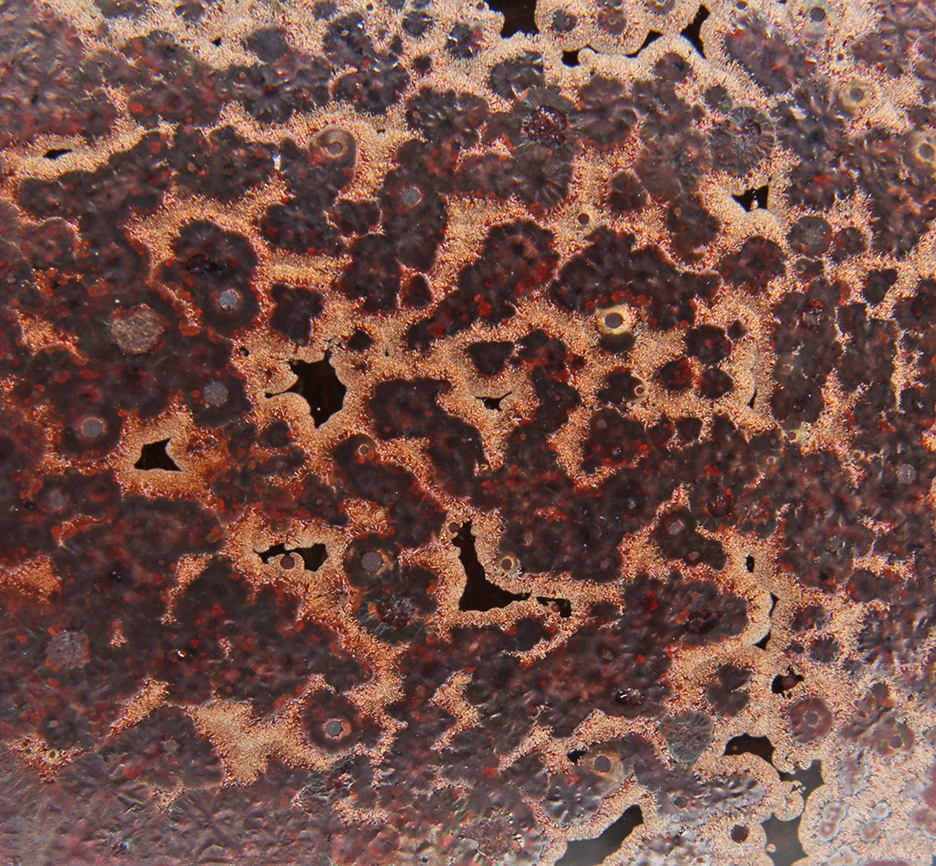

a close up of a small section of the glaze

In the closeup one sees a complex growth of several different overlaping crystals.

This glaze was inspired by the observation that Li2O is more active than

either K2O or Na2O, I'm pushing the edge -

asking how much Li2O can a

glaze absorb.

As is seen from the close up, the glaze is highly textured.

The folds are in the surface of the glaze.

It would appear

that the surface of the glaze freezes while the bulk glaze beneath remains

molten.

At the foot of this pot, a roll of glaze over a quarter inch

thick had formed, and bits of that have flaked off.

This glaze is weak,

owing to its high alkali metal content. The next step will be to scale back

the alkali content,

hopefully improve the mechanical properties while

maintaining the surface crystals.