copper Red

Here are three local reduction copper glaze. These glazes are neither as high

in silica nor as fluid as the usual copper red glaze.

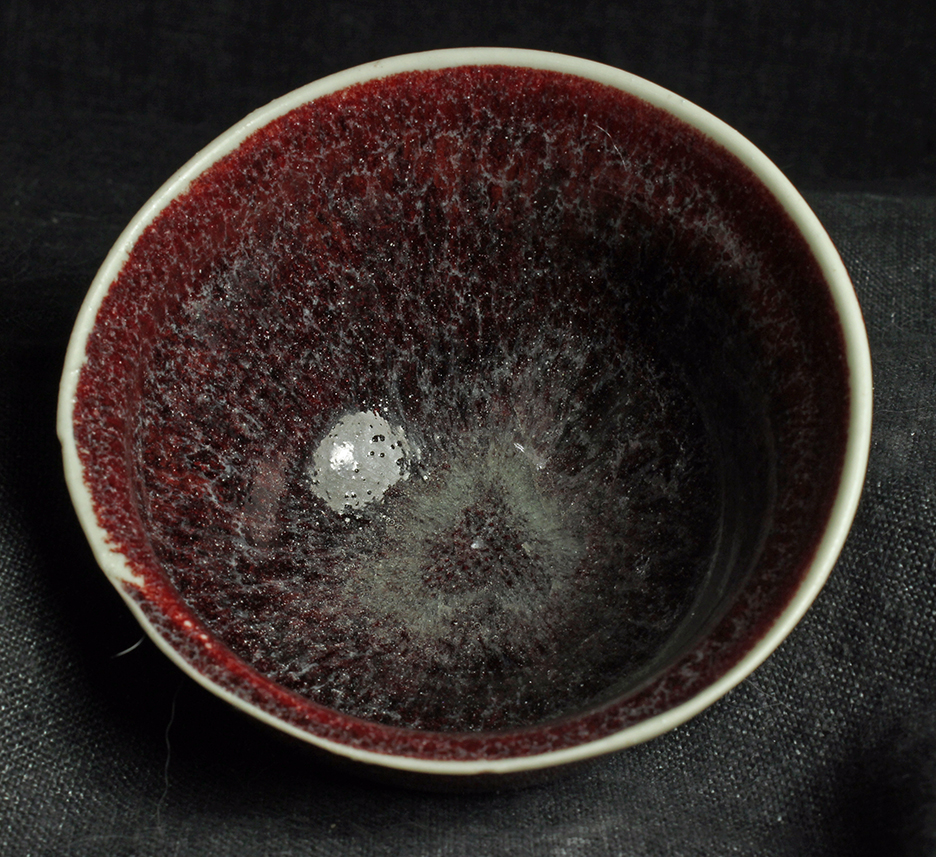

inside of bowl:

Outside of bowl:

inside of bowl:

Outside of bowl:

inside of bowl:

Outside of bowl:

150 deg F an hour to 250 deg F

400 deg F an hour to 1800 deg F

300 deg F an hour to 2050 deg F

120 deg F an hour to 2310 deg F with a hold of 20 minutes at 2310 deg F

300 deg F an hour to 1750 deg F then a half hour hold at 1750 deg F

300 deg F an hour to 1700 deg F then a Three hour hold at 1700 deg F

25 deg F an hour to 1650 deg F then a one hour hold at 1650 deg F

The glaze with added .5% copper carbonate, 2% tin oxide, and 1% silicon

carbide.

K2O .09

Al2O3 .43

SiO2 3.13

molecular percent Silica 68%

The glaze with added .5% copper carbonate, 2% tin oxide, and 1% silicon

carbide.

K2O .08

Al2O3 .48

SiO2 2.65

molecular percent Silica 64%

The glaze with added .5% copper carbonate, 2% tin oxide, and 1% silicon

carbide.

K2O .13

Al2O3 .48

SiO2 2.64

molecular percent Silica 64%

These are non-traditional formulations for a copper red glaze; these glazes

have lower silica:alumina ratio and higher alumina

The effect of lower silica:alumina ratio and higher alumina is higher

viscosity. Increased viscosity reduces oxygen movement

The use of a local reduction agent to produce colloidal copper is a one time

event at the time of the decomposition of the silicon carbide;

The first glaze, cuRed_Z20_0, is the most fluid of these glazes.

It is a bluish red; and displays the least

The pair of glazes alexanderBowl_Z15_0; and alexanderBowl_Z15_1 have

the same silica:alumina ratio and alumina and both have

However alexanderBowl_Z15_1 has higher alkali metals; so, as expected, is a

more fluid glaze.

As seen in the second pair of pictures, alexanderBowl_Z15_0 is a mixed

lilac and grey-aqua.

alexanderBowl_Z15_1, equally mixed, is red and grey-green, as seen in the last

pair of pictures.

The first of

these glazes is nearly a full gloss, is maroon, with only a slight overlay of

grey white frosty tracings.

The other two glazes, with lower alkali

metals, and lower silica are microcrystalline semi-matte glazes and are mixed

red and grey green.

Glaze cuRed_Z20_0 with copper carbonate

Glaze alexanderBowl_Z15_0 with copper carbonate

Glaze alexanderBowl_Z15_1 with copper carbonate

bowls are ~4 inches in diameter

oxidation firing to cone 10 in an electric kiln

Firing profiles

Up Fire profile

Down Fire Profile

Clay body is a grolleg porcelain from Tacoma Clay Art Center.

glaze compositions

Empirical Formula glaze cuRed_Z20_0 :

Na2O .2

CaO .27

MgO .08

SrO .28

ZnO .08

SnO2 .05

Empirical Formula glaze alexanderBowl_Z15_0 :

Na2O .05

CaO .7

MgO .17

Empirical Formula glaze alexanderBowl_Z15_1 :

Na2O .05

CaO .63

MgO .19

Remarks

than is usual in copper red

glazes.

into and within the

glaze. As a result colloidal copper particles are not as rapidly

re-oxidized.

as a

result, re-oxidation of the copper is not easily controlled.

of the cloudy grey second

phase, but has streaky incomplete coverage, especially on the outside where

the glaze

application was thinner. This is seen in the first two pictures.

a prominent grey-aqua

second phase.