Reactions at the interface between two glazes

The interaction at the interface of adjacent glazes.

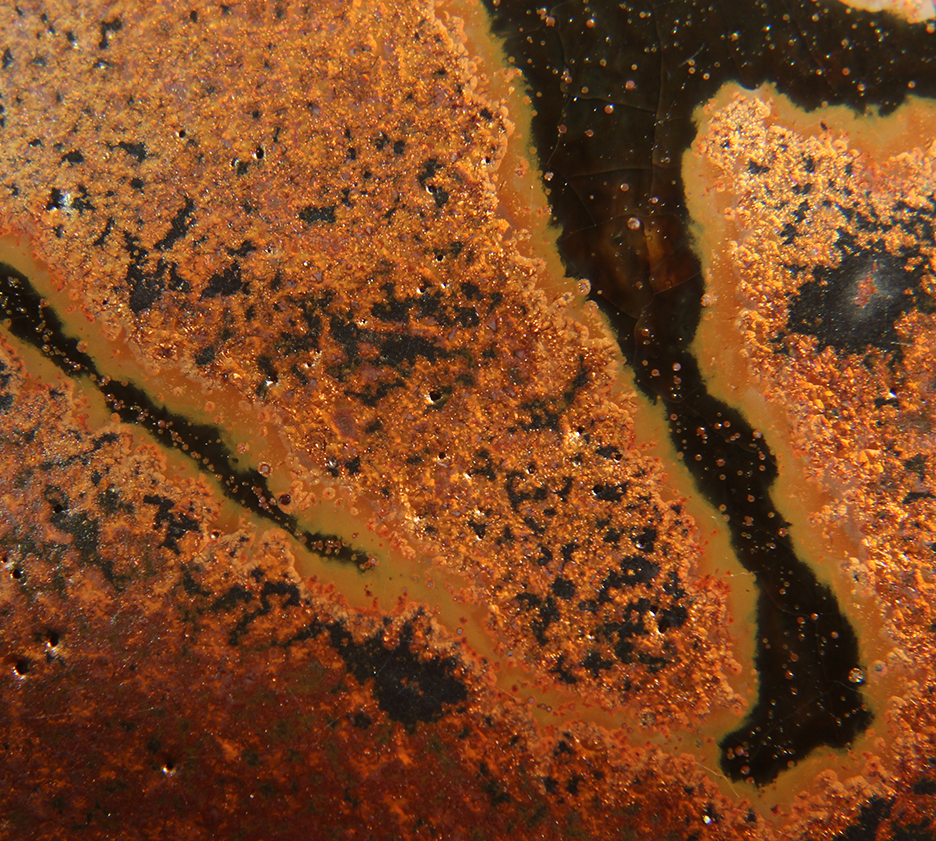

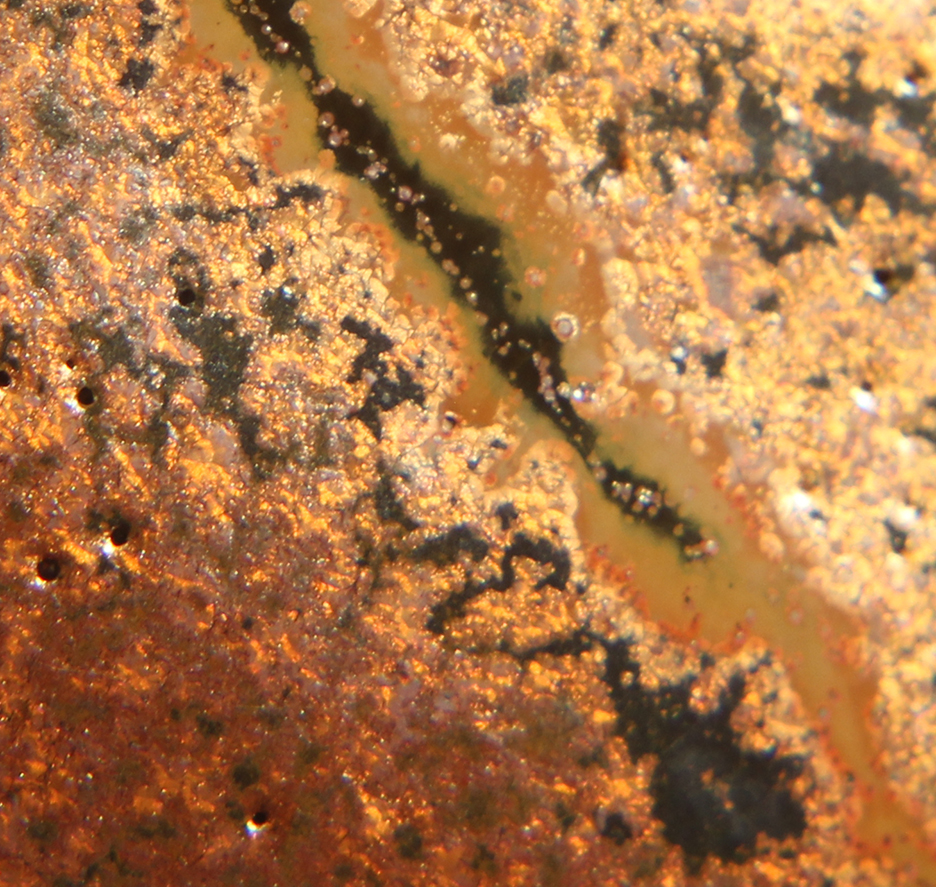

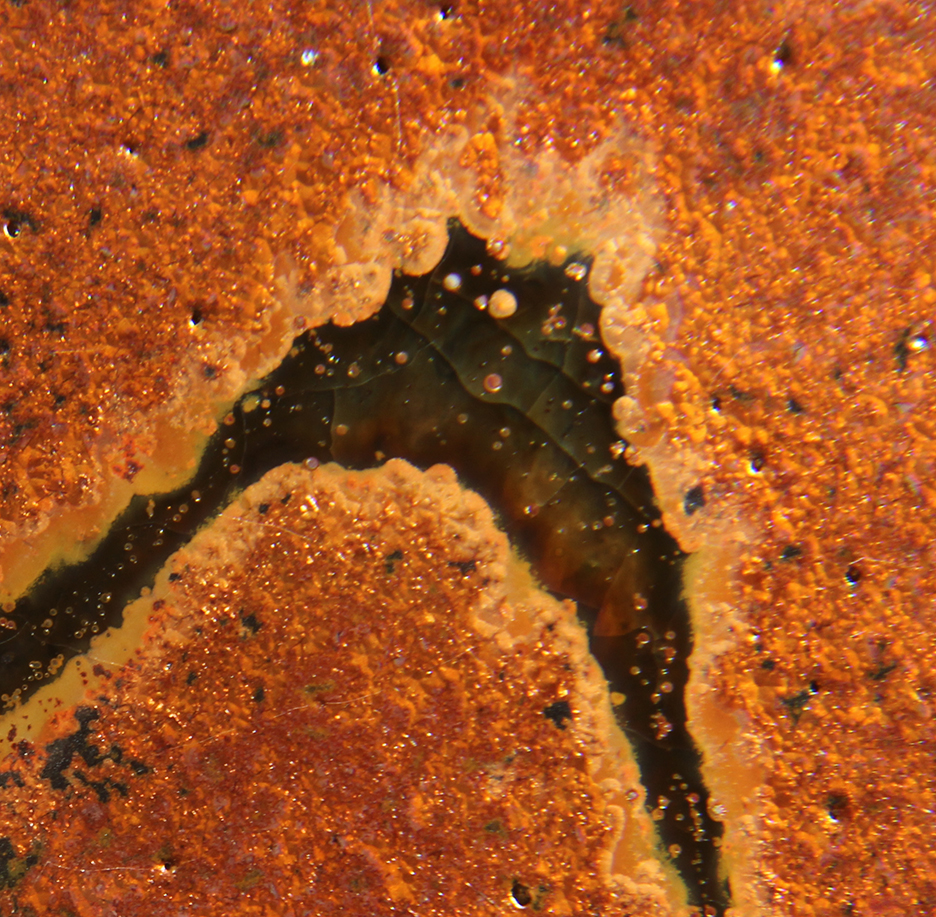

Several closeups of the interaction region of the two glazes are shown and,

for context, a picture of the pot.

The background glaze is satIron_ZG_1S_1Munge_1, the foreground design is

glazed with satIron_ZG_1O_1Q_1MFe

The design is created by adhering a mask and then applying the main

glaze. After drying, the entire pot is coated in wax,

150 deg F an hour to 250 deg F

400 deg F an hour to 1800 deg F

300 deg F an hour to 2050 deg F

120 deg F an hour to 2310 deg F with a hold of 20 minutes at 2310 deg F

300 deg F an hour to 1750 deg F then a half hour hold at 1750 deg F

300 deg F an hour to 1700 deg F then a Three hour hold at 1700 deg F

25 deg F an hour to 1650 deg F then a one hour hold at 1650 deg F

K2O .06

Al2O3 .54

SiO2 3

molecular percent Silica 61%

K2O .24

Al2O3 .47

SiO2 3.17

molecular percent Silica 66%

The interaction region replaced nearly half of the original design.

The inlay glaze ate into

The inlay melts, diffuses into the matrix of background glaze, it seeps into

the background, eating as it goes.

The design glaze, satIron_ZG_1O_1Q_1MFe is substantially more fluid than the

background glaze which is higher

The contrasting viscosity of the two glazes creates a dynamic interaction region.

then the mask is removed

and the open area filled in with a second glaze.

Close up Images of the interaction region

Image of the piece

bowl with glaze satIron_ZG_1S_1Munge_1 and inlay satIron_ZG_1O_1Q_1MFe

bowl is ~10 inches in diameter

oxidation firing to cone 10 in an electric kiln

Firing profiles

Up Fire profile

Down Fire Profile

Clay body is a grolleg porcelain from Tacoma Clay Art Center.

glaze compositions

Background glaze

Empirical Formula satIron_ZG_1S_1Munge_1 :

Na2O .53

Li2O .2

CaO .2

MgO .01

Fe2O3 .21

P2O5 .17

Inlay Glaze

satIron_ZG_1O_1Q_1MFe :

Na2O .22

Li2O .24

CaO .16

MgO .14

Fe2O3 .09

P2O5 .04

Remarks

the background glaze

replacing a sharp edge with a ragged edge reminiscent of melting snow.

The decoration glaze diffuses into the

background leaving behind

partially melted crystals of the background

floating on/in a contaminated version of the matrix glaze.

in both silica and phosphorus, and lower

in Alumina.

Both glazes are high in alkali metals.