Copper Colors

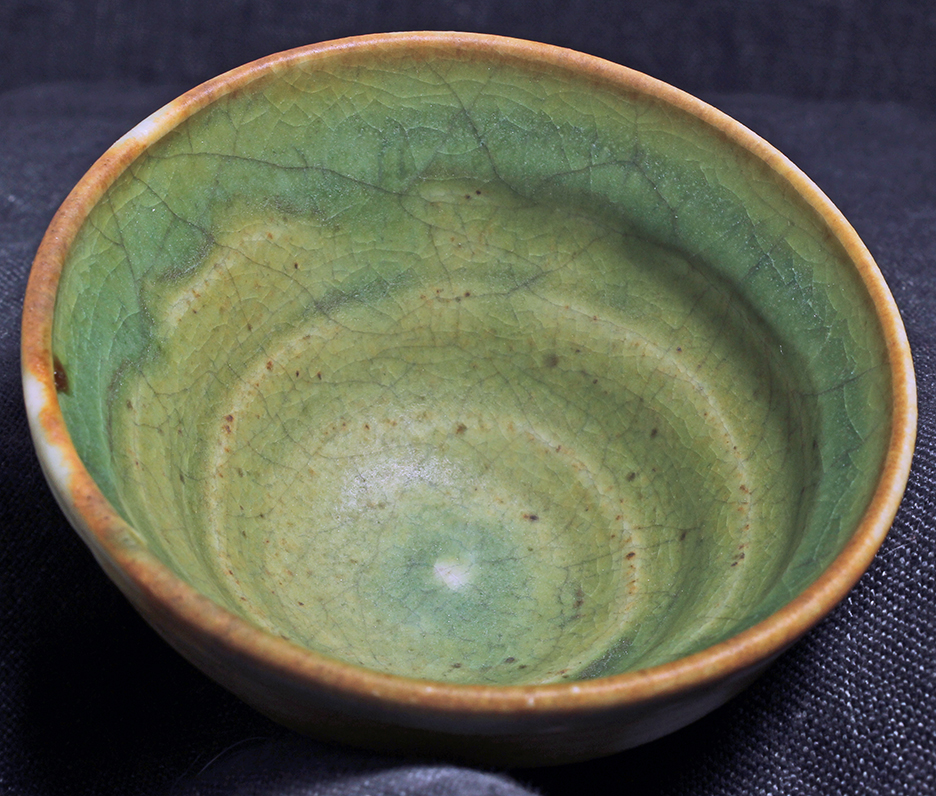

Application thickness influences the final color of this glaze. If thin, this

glaze is a variegated golden yellow-brown

This glaze is fired in an electric kiln with no local reducing agent, showing

that copper can produce yellow without reduction.

This firing, in addition to having a slow downfire, also has a slow upfire.

The peak temperature is lowered in order to avoid

inside of bowl:

Outside of bowl:

150 deg F an hour to 250 deg F

400 deg F an hour to 1770 deg F

300 deg F an hour to 1850 deg F

120 deg F an hour to 2130 deg F

13 deg F an hour to 2180 deg F with a two hour hold

13 deg F an hour to 2210 deg F with a three hour hold

300 deg F an hour to 1900 deg F then a three hour hold at 1900 deg F

300 deg F an hour to 1850 deg F then a Three hour hold at 1850 deg F

This glaze has 1.5% Copper Carbonate added

K2O 0.13

Al2O3 0.71

SiO2 3.25

molecular percent Silica 65.5%

Not the intended, yet an interesting glaze, both the color and texture.

Is the color that of cuprous oxide? If so, how did copper in the lower

oxidation state occur with no reduction of any form?

This glaze is underfired, as shown by the intense crazing.

This is a cone 10 firing, at a temperature which with a faster rate of heating

in an electric kiln would be cone 8.

I do not know why underfiring would result in a lower oxidation state for the

copper.

micro-crystalline matte. This is

best seen in a broad swath on the outside near the rim. If application

thickness

increases, it becomes green with a spattering of yellow-brown, and

if it is applied even more thickly, green dominates.

the retarded upfire

causing the kiln to reach a higher cone.

copperYellow_Z24_0

bowl is ~3 inches in diameter

oxidation firing to cone 10 in an electric kiln

Firing profiles

Up Fire profile

Down Fire Profile

Clay body is a grolleg porcelain from Tacoma Clay Art Center.

glaze compositions

Empirical Formula glaze copperYellow_Z24_0 :

Na2O 0.42

CaO 0.24

MgO 0.11

SrO 0.10

Remarks

Chemical reactions depend on absolute

temperature as well as heat work.