Migrating abutting glazes

The interface of adjacent glazes.

Several closeups of the interaction region of the two glazes are shown and,

for context, a picture of the pot.

The background glaze is tsabar-harris-red; the foreground design is

glazed with iron_8_R_C10_13PSi.

The design is created by adhering a mask and then applying the main

glaze. After drying, the entire pot is coated in wax,

150 deg F an hour to 250 deg F

400 deg F an hour to 1800 deg F

300 deg F an hour to 2050 deg F

120 deg F an hour to 2310 deg F with a hold of 20 minutes at 2310 deg F

300 deg F an hour to 1750 deg F then a half hour hold at 1750 deg F

300 deg F an hour to 1700 deg F then a Three hour hold at 1700 deg F

25 deg F an hour to 1650 deg F then a one hour hold at 1650 deg F

K2O 0.21

Al2O3 0.51

SiO2 2.88

molecular percent Silica 65%

added:

Copper Carbonate 0.5%

Silicon Carbide 0.5%

K2O 0.11

Al2O3 0.56

SiO2 3.12

molecular percent Silica 63%

The inlay glaze is a saturated iron glaze high in alkali metals containing

CaO; the background glaze is high in Calcium,

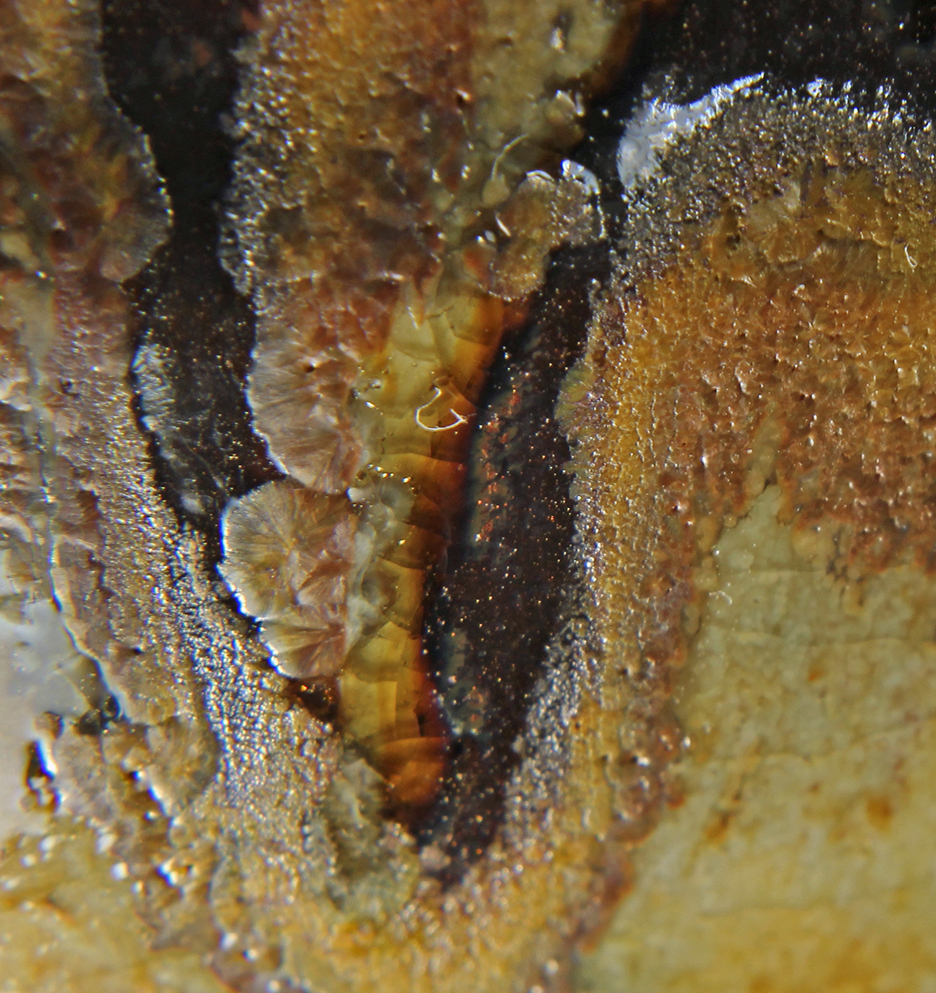

Micro-crystals grow more profusely in the interaction region than in

either background or foreground glaze,

The bronze part of the interface just above the matrix is covered in

crystals, which are only faintly visible

The interaction regions is the result of gravity and diffusion. The fluid

inlay, applied thickly, flows down the

then the mask is removed

and the open area filled in with a second glaze.

Close up Images of the interaction region

Image of the piece

bowl with glaze glaze tsabar-harris-red and inlay iron_8_R_C10_13PSi

bowl is 4.5 inches in diameter

oxidation firing to cone 10 in an electric kiln

Firing profiles

Up Fire profile

Down Fire Profile

Clay body is a grolleg porcelain from Tacoma Clay Art Center.

glaze compositions

Background glaze

Empirical Formula tsabar-harris-red :

Na2O 0.07

CaO 0.65

MgO 0.01

ZnO 0.06

Fe2O3 0.02

Inlay Glaze

Empirical Formula iron_8_R_C10_13PSi :

Na2O 0.45

Li2O 0.25

CaO 0.17

MgO 0.02

Fe2O3 0.28

Remarks

contains Zinc and has

moderate alkali metals. The background glaze is viscous,

the inlay glaze

fluid.

and dominate the interaction region.

in the photographs. These

regions are marked by pits at the corners of the lattice between the abutting

crystals,

some of which are 1/4 inch in diameter. These crystals are

slightly domed, obscuring the radial needles in the crystals.

near vertical wall of the pot.

Additionally, there are regions of the design where the iron in the inlay can

be seen to have migrated

sideways via diffusion from high concentration

in the inlay to low concentration in the matrix.