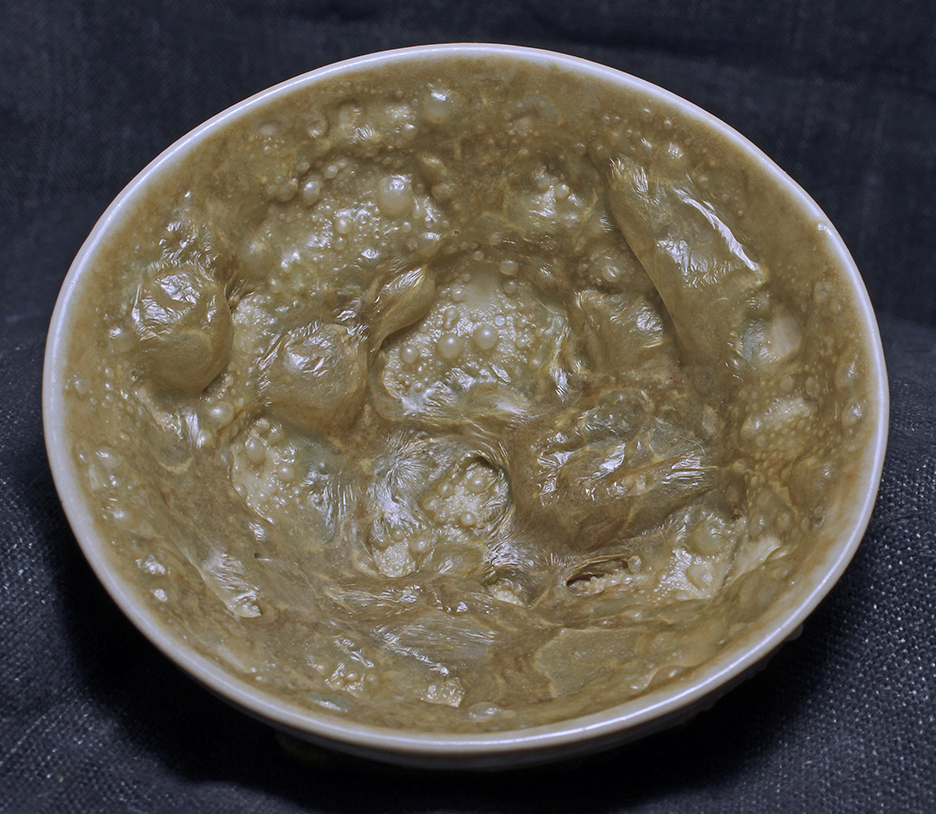

Surprising non glaze

This non-glaze is covered in un-popped bubbles. With rather rough handling

these bubbles haven't popped. Much gas

The glaze, longquan-n-song-tsabar-Z2S, from which this glaze, ru-tsabar-Z2T-0,

is derived is semi-matte with variegated orange markings.

I'd thought to stabilize the matte texture and increase the prominence of the

markings with a moderate increase in alumina and silica.

inside of bowl:

Outside of bowl:

inside of bowl:

Outside of bowl:

150 deg F an hour to 250 deg F

400 deg F an hour to 1800 deg F

300 deg F an hour to 2050 deg F

120 deg F an hour to 2310 deg F with a hold of 20 minutes at 2310 deg F

300 deg F an hour to 1750 deg F then a half hour hold at 1750 deg F

300 deg F an hour to 1700 deg F then a Three hour hold at 1700 deg F

25 deg F an hour to 1650 deg F then a one hour hold at 1650 deg F

This glaze has 0.2% silicon carbide added for local reduction.

K2O 0.19

Al2O3 0.56

SiO2 2.76

molecular percent Silica 63.6%

This glaze has 0.2% silicon carbide added for local reduction.

K2O 0.16

Al2O3 0.6

SiO2 3.12

molecular percent Silica 65.6%

Increasing both alumina and silica while maintaining a constant silica alumina

ratio is equivalent to decreasing the basic components

It's as if there are two glazes here, one which melts low and flows, and

another which when it starts to melt can't de-gass through the

must have been generated

to have produced that froth of bubbles. Where did it come from, and why are

the bubbles so strong?

If thickly

applied longquan-n-song-tsabar-Z2S is glossy, uniform and semi-opaque,

a rather insipid milky glass white.

Instead, the

result is the bubbled confection seen below.

longquan-n-song-tsabar-Z2S

ru-tsabar-Z2T-0

bowls are ~3 inches in diameter

oxidation firing to cone 10 in an electric kiln

Firing profiles

Up Fire profile

Down Fire Profile

Clay body is a grolleg porcelain from Tacoma Clay Art Center.

glaze compositions

Empirical Formula glaze longquan-n-song-tsabar-Z2S :

Na2O 0.06

CaO 0.62

MgO 0.07

ZnO 0.06

Fe2O3 0.01

Empirical Formula glaze ru-tsabar-Z2T-0 :

Na2O 0.07

Li2O 0.06

CaO 0.59

MgO 0.08

ZnO 0.04

Fe2O3 0.02

Remarks

of the glaze,

those components in the first column of the seger formula. Here the silica

also is increased. The second glaze,

the one with the bubbles, has less

flux.

already

melted surface layer.