underfired

The glaze cooper_404_1_PAl is underfired.

Several closeups of the surface are shown and, for context, a picture

of the pot.

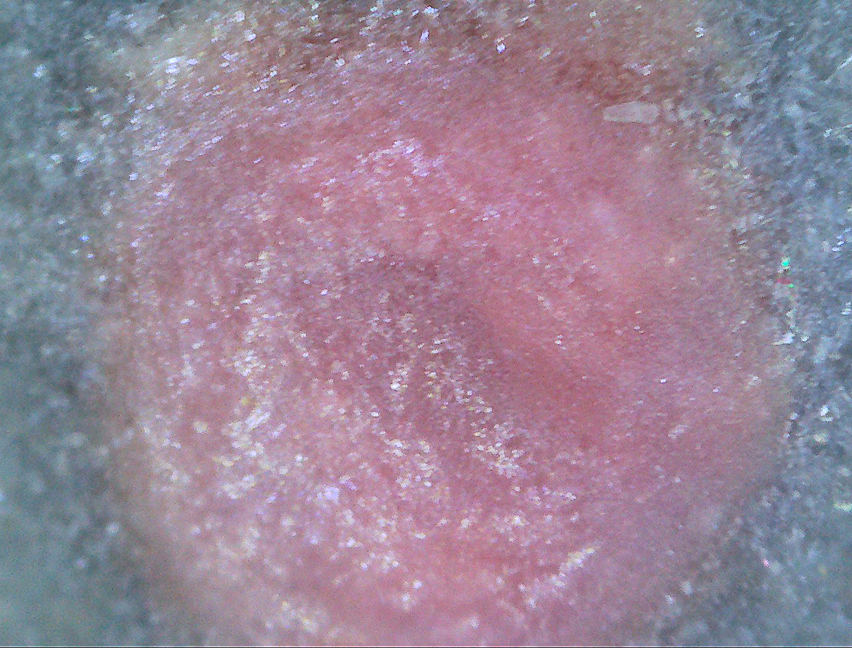

There is a pink artifact which perhaps is the result of inhomogeneity in the

glaze mixture. I suspect it is the ZnO

150 deg F an hour to 250 deg F

400 deg F an hour to 1800 deg F

300 deg F an hour to 2050 deg F

120 deg F an hour to 2310 deg F with a hold of 20 minutes at 2310 deg F

300 deg F an hour to 1750 deg F then a half hour hold at 1750 deg F

300 deg F an hour to 1700 deg F then a Three hour hold at 1700 deg F

25 deg F an hour to 1650 deg F then a one hour hold at 1650 deg F

K2O 0.14

Al2O3 0.38

SiO2 2.38

molecular percent Silica 63%

Added 1.5% Nickel Oxide

The close-up pictures were taken with a digital microscope.

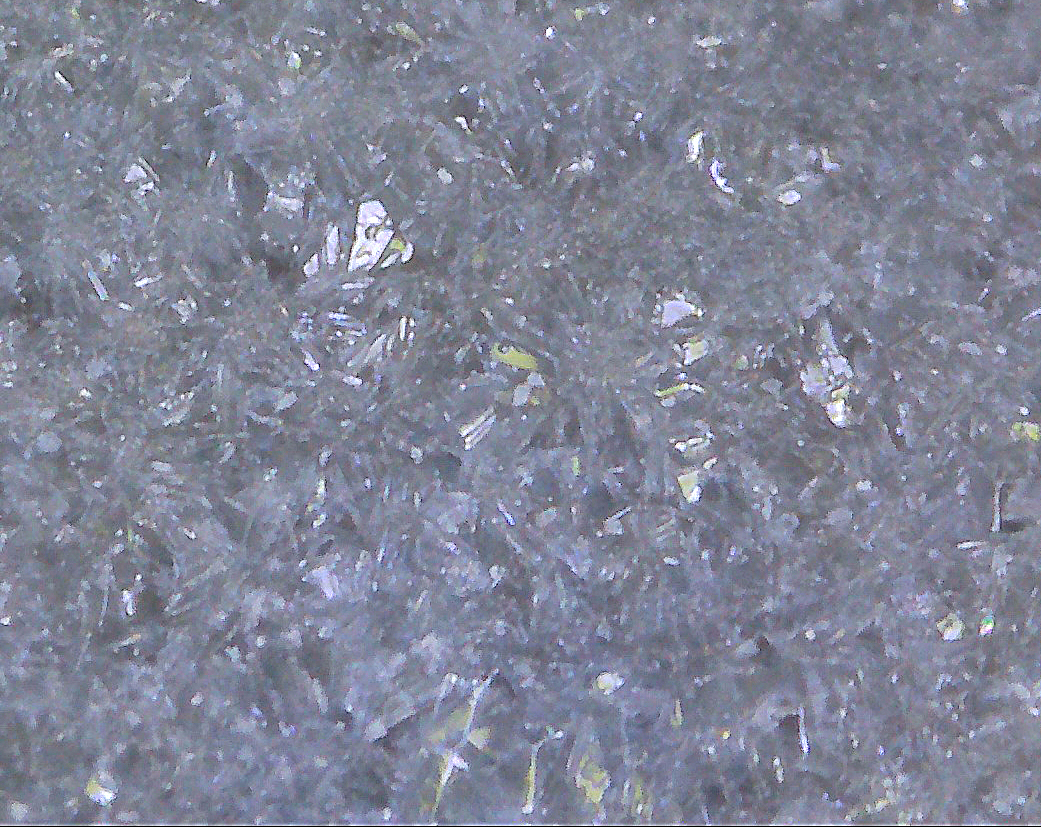

The coarse-grained microcrystalline structure of the surface shows this

glaze to be underfired. The pits that appear

The roll of glaze at the bottom of the pot, showing alumina picked up from the

shelf, shows this to be an exceedingly fluid melt.

Here is a composition which, while it didn't mature into a glaze (i.e. is

underfired), is more fluid than one would desire a glaze to be.

which is not fully mixed into the

glaze.

Close up Images of the surface

Image of the piece

inside

outside

bowl is is 4 inches in diameter

oxidation firing to cone 10 in an electric kiln

Firing profiles

Up Fire profile

Down Fire Profile

Clay body is a grolleg porcelain from Tacoma Clay Art Center.

glaze compositions

Empirical Formula cooper_404_1_PAl :

Na2O 0.22

CaO 0.02

MgO 0.01

BaO 0.22

ZnO 0.39

Remarks

to be pinholes are seen in the

enlargements as edged in micro-crystals. These are voids created by

continuation

of the chemical reactions that are part of forming the melt.

They are not the residue of escaping gas from an already melted glaze.