Migrating disparate abutting glazes

The interface of adjacent glazes from divergent glaze families.

The matrix glaze is a high iron glaze, high in alkali metals and

alumina, the inlay glaze by contrast

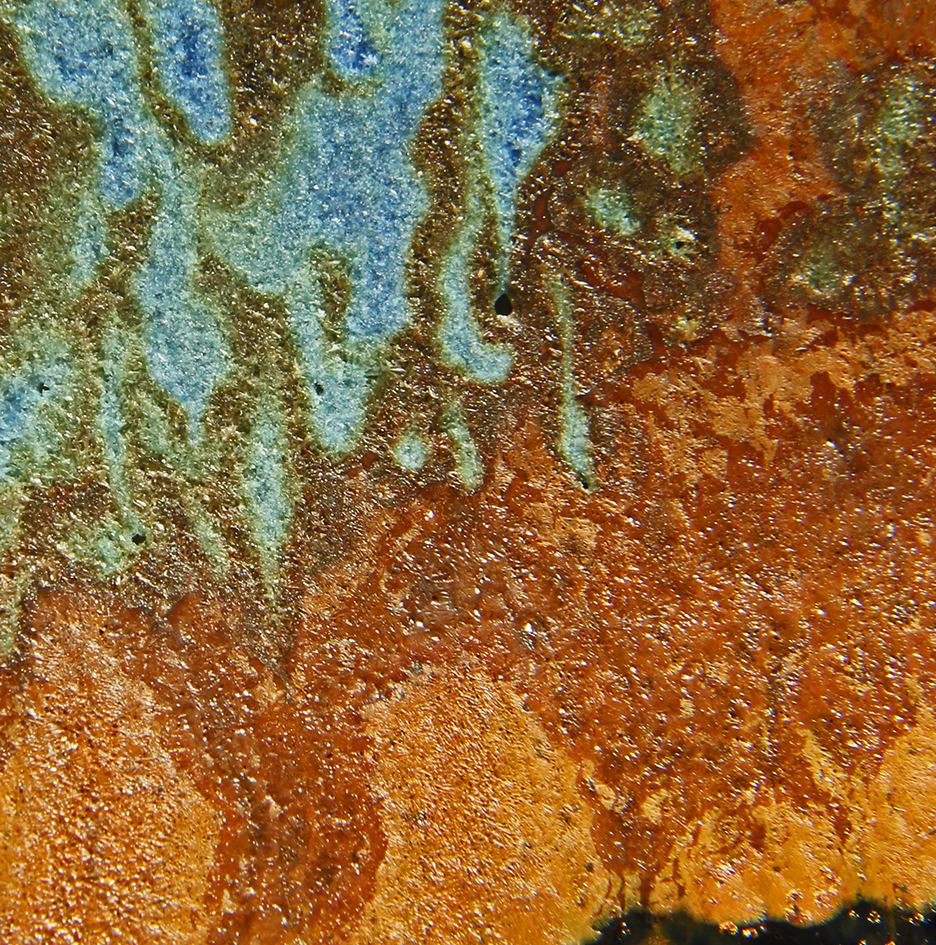

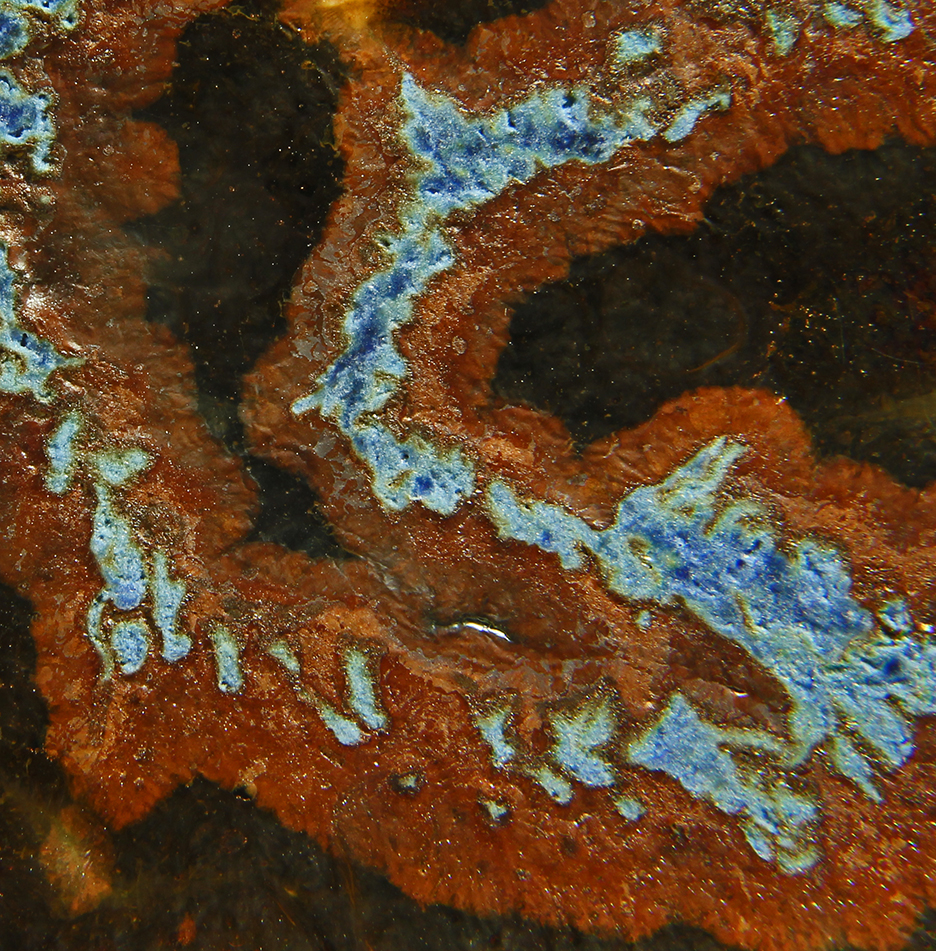

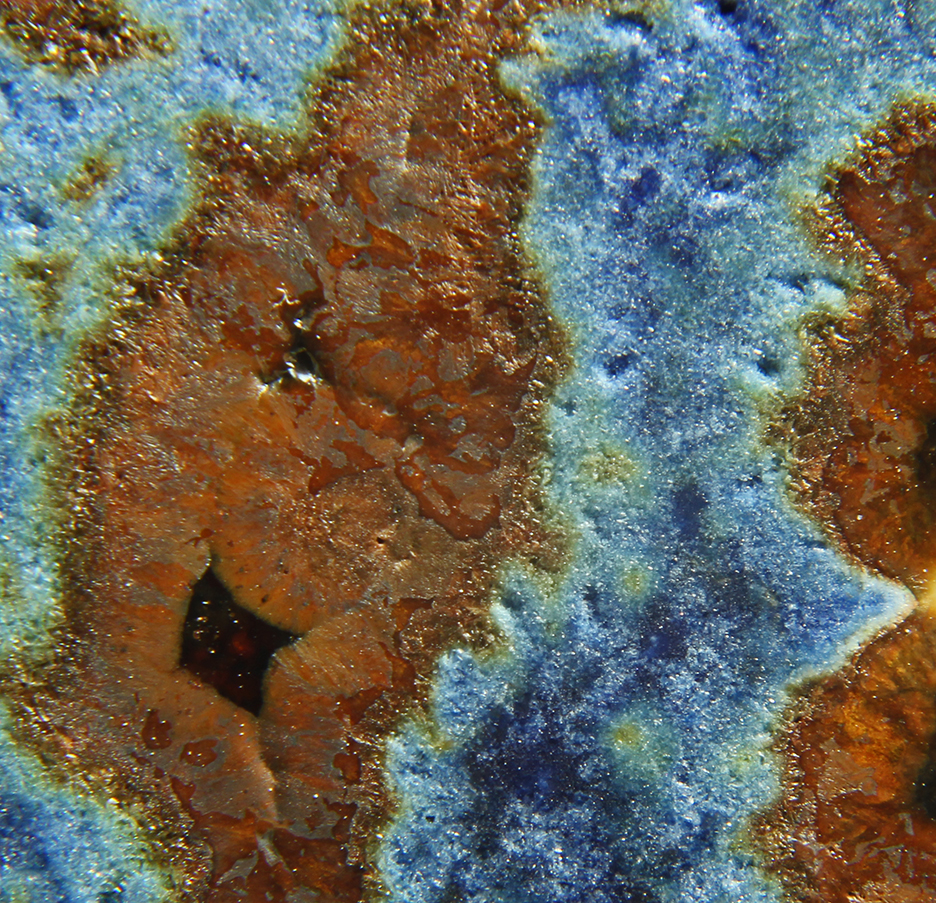

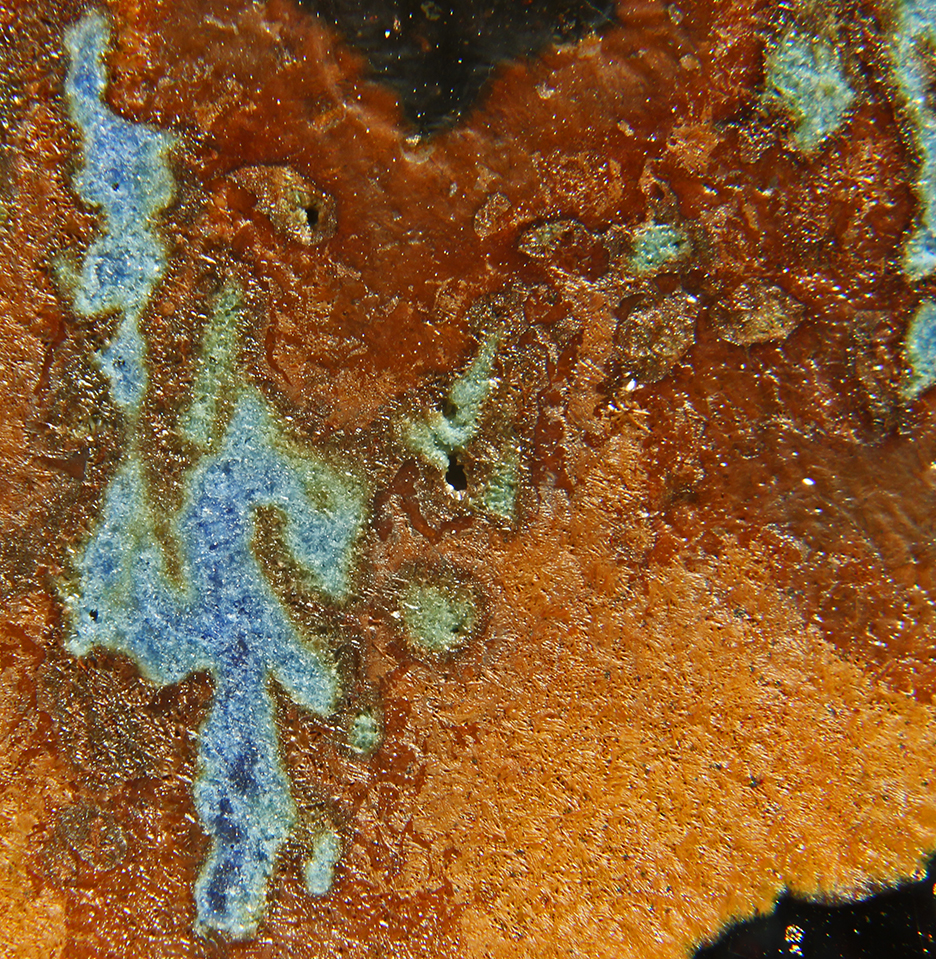

Several closeups of the interaction region of the two glazes are shown and,

for context, a picture of the pot.

The background glaze is satIron_ZG_Ip7_5; the foreground design is

glazed with hankPaper_Z1R_2C_1.

The design is created by adhering a mask and then applying the main

glaze. After drying, the entire pot is coated in wax,

150 deg F an hour to 250 deg F

400 deg F an hour to 1800 deg F

300 deg F an hour to 2050 deg F

120 deg F an hour to 2310 deg F with a hold of 20 minutes at 2310 deg F

300 deg F an hour to 1750 deg F then a half hour hold at 1750 deg F

300 deg F an hour to 1700 deg F then a Three hour hold at 1700 deg F

25 deg F an hour to 1650 deg F then a one hour hold at 1650 deg F

K2O 0.07

Al2O3 0.71

SiO2 3.13

molecular percent Silica 63%

K2O 0.12

Al2O3 0.42

SiO2 2.7

molecular percent Silica 63%

Added:

1% Cobalt Carbonate

.67% Copper Carbonate

The

matrix glaze is higher in alkali metals, silica and alumina, while the inlay

glaze is high in BaO and SrO.

The mask for the inlay is a series of linked ovoids, a large part of the area

within these ovoids is a mix of

The matrix glaze was excessively thickly applied, resulting in the visible

crawling. That heavy application, however,

is high in alkaline earths, lower in

alumina and contains titanium.

then the mask is removed

and the open area filled in with a second glaze.

Close up Images of the interaction region

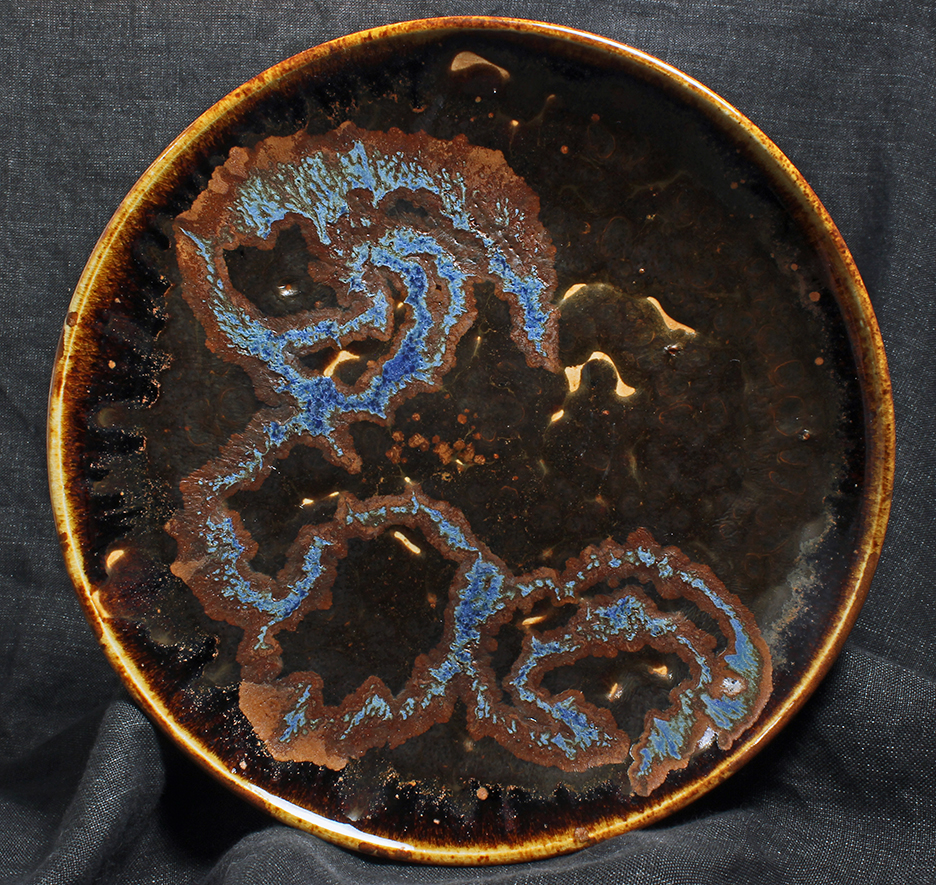

Image of the piece

plate with glaze satIron_ZG_Ip7_5 and inlay hankPaper_Z1R_2C_1

plate is 10 inches in diameter

oxidation firing to cone 10 in an electric kiln

Firing profiles

Up Fire profile

Down Fire Profile

Clay body is a grolleg porcelain from Tacoma Clay Art Center.

glaze compositions

Background glaze

Empirical Formula satIron_ZG_Ip7_5 :

Na2O 0.43

Li2O 0.20

CaO 0.13

MgO 0.17

Fe2O3 0.1

P2O5 0.04

Inlay Glaze

Empirical Formula hankPaper_Z1R_2C_1 :

Na2O 0.12

Li2O 0.05

CaO 0.14

MgO 0.02

BaO 0.31

SrO 0.24

TiO2 0.14

Remarks

Both these glazes are exceedingly fluid.

inlay glaze and matrix glaze.

increased the running together

and merging of the two glazes. This pair of glazes work wonderfully

together,

but require balancing the required thickness of the matrix

for the effects, yet avoiding crawling.