Interacting glazes at a vertical interface

Glazes interacting at a vertical interface.

The matrix (i.e. background) glaze and inlay glaze do not overlap before

firing.

The matrix glaze is a microcrystalline matte, as seen in both the close

up images, and in the image of the mug.

As the background and inlay glaze differ substantially in composition, the

micro-crystals which develop

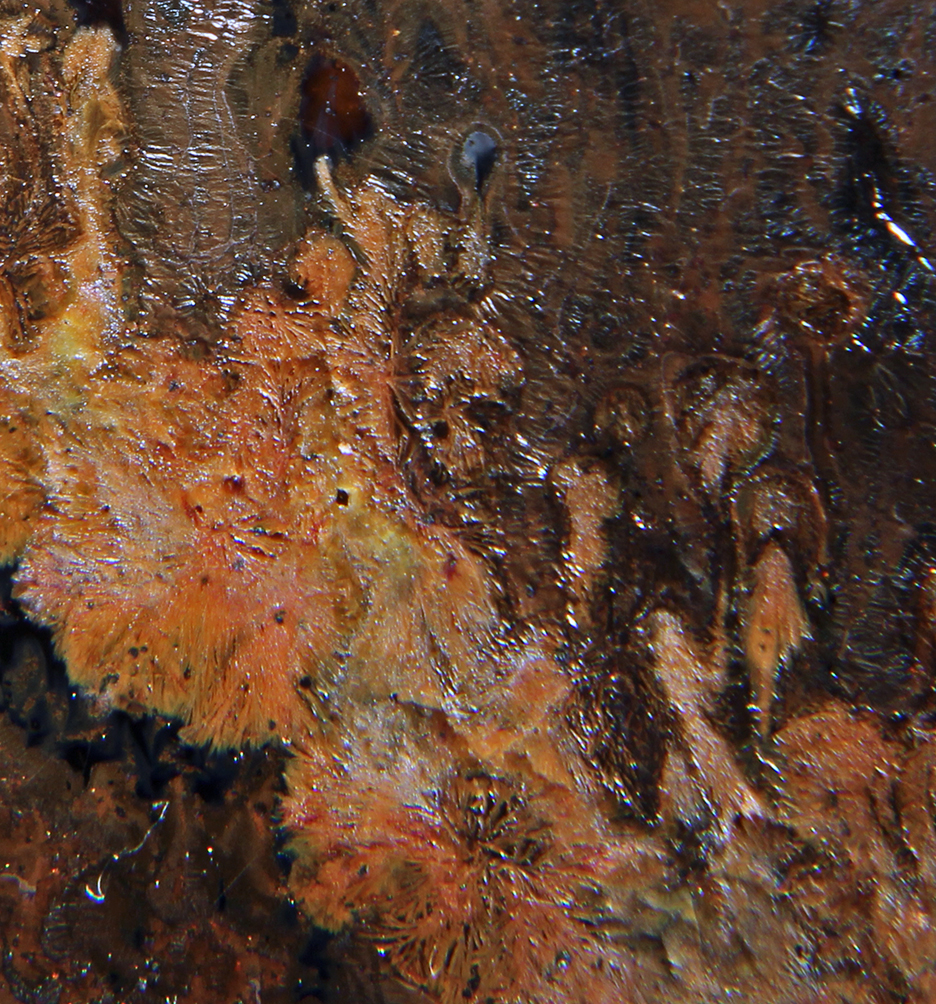

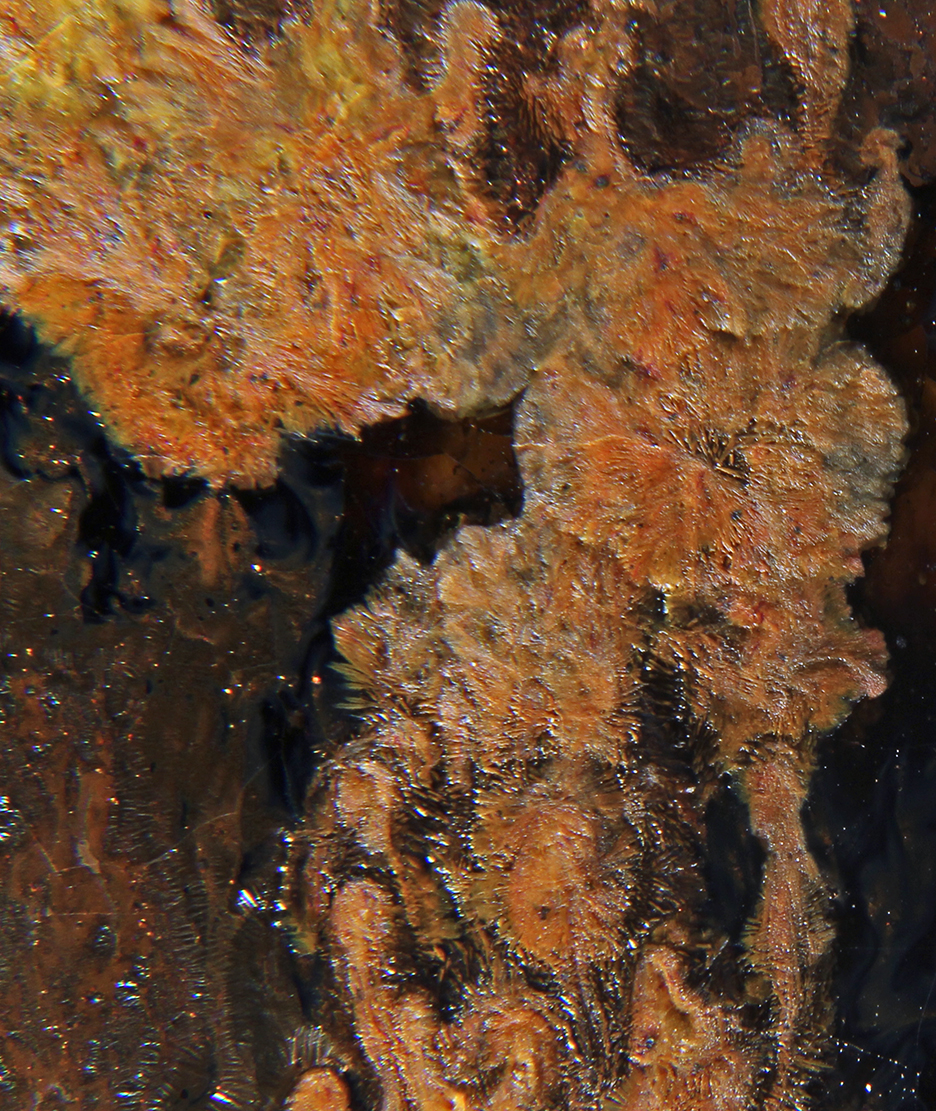

Several closeups of the interaction region of the two glazes are shown and,

for context, a picture of the pot.

The background glaze is longquan-iron-shino-Z38-0, the inlay design is

glazed with iron_Alex_1MFe

The design is created by adhering a mask and then applying the main

glaze. After drying, the mask is removed

150 deg F an hour to 250 deg F

400 deg F an hour to 1800 deg F

300 deg F an hour to 2050 deg F

120 deg F an hour to 2310 deg F with a hold of 20 minutes at 2310 deg F

300 deg F an hour to 1750 deg F then a half hour hold at 1750 deg F

300 deg F an hour to 1700 deg F then a Three hour hold at 1700 deg F

25 deg F an hour to 1650 deg F then a one hour hold at 1650 deg F

K2O 0.14

Al2O3 0.97

SiO2 3.6

molecular percent Silica 62.6%

K2O 0.07

Al2O3 0.53

SiO2 2.97

molecular percent Silica 64.6%

The original inlay, as placed in the kiln was a simple curve, about 3/8th of

an inch thick. All else is the

The variously colored crystals near the edge of the interaction region show

diffusion of iron and alkali metals

The troughs cut in the inlay by rivulets of the background glaze are evidence

of the background glaze preferentially

While melted, both background and inlay glazes are comprised of both

liquid and crystals; four components,

The inlay glaze

also is a microcrystalline matte. It is seen

here , with higher iron.

in the two glazes are distinct. In the

interface between these two micro-crystalline matte glazes, are seen

crystals not otherwise seen in either glaze. In particular, note the

thread-like microcrystals seen

in several of the closeups.

and the open area filled in with a

second glaze, using a bulb syringe with a needle applicator.

Close up Images of the interaction region

Image of the piece

mug with glaze longquan-iron-shino-Z38-0 and inlay glaze

iron_Alex_1MFe.

mug is ~3.5 inches in high

oxidation firing to cone 10 in an electric kiln

Firing profiles

Up Fire profile

Down Fire Profile

Clay body is a grolleg porcelain from Tacoma Clay Art Center.

glaze compositions

Background glaze

Empirical Formula longquan-iron-shino-Z38-0 :

Na2O 0.44

Li2O 0.20

CaO 0.17

MgO 0.05

Fe2O3 0.17

Inlay Glaze

Empirical Formula iron_Alex_1MFe:

Na2O 0.34

Li2O 0.11

CaO 0.37

MgO 0.11

Fe2O3 0.08

P2O5 0.02

Remarks

result of the erosion of the inlay glaze by

flowing/diffusing of the background glaze.

from the background glaze into the inlay

crystals.

eating through the fault lines

in the micro-crystalline inlay glaze. In turn, the glossy black regions are

the

remains of the background and inlay reacting so completely that a new

glaze has emerged.

all with distinct compositions and

mobilities. The interactions between these four different components created

the

various effects described above.