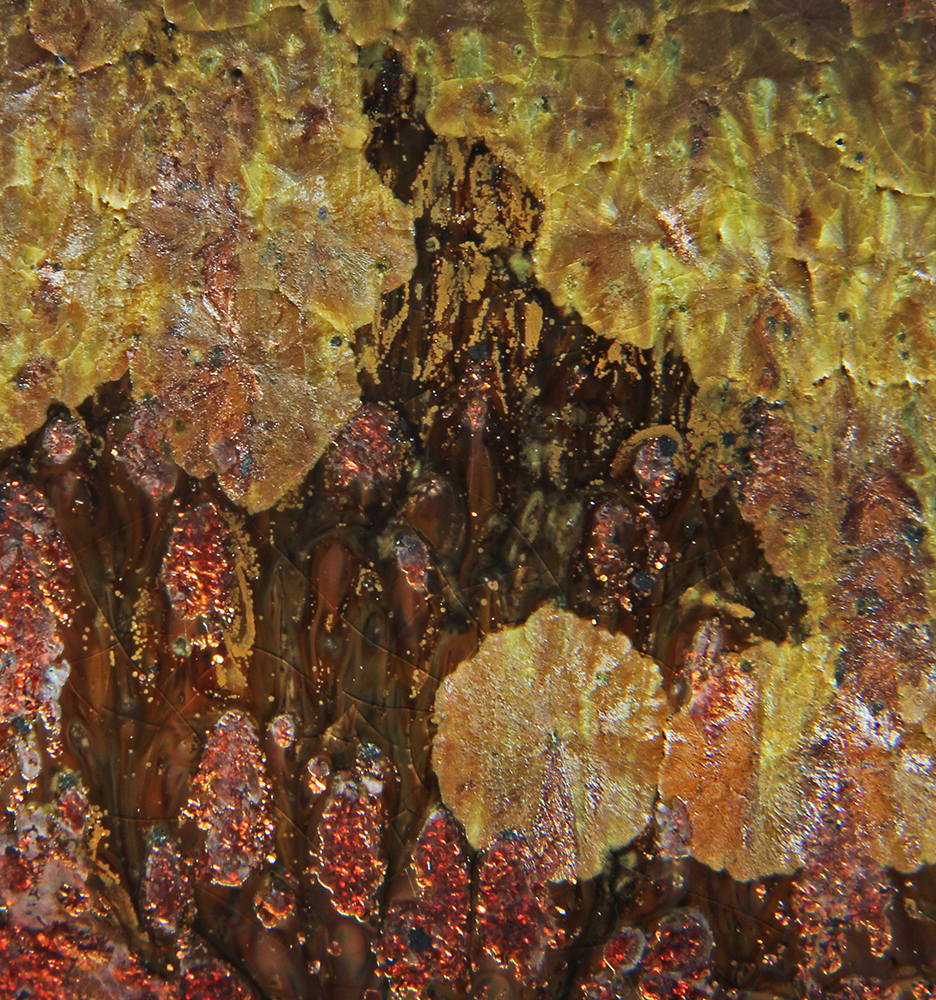

disparate glazes at a vertical interface

Disparate glazes meeting at a vertical interface. The matrix (i.e. background)

glaze and inlay glaze overlap

The matrix glaze is a high iron, high alkali metal glaze. The inlay glaze, by

contrast,

Several closeups of the interaction region of the two glazes are shown and,

for context, a picture of the pot.

The background glaze is satIron_ZG_0, the foreground design is

glazed with alexanderBowl_0_Z1Y.

A thick glaze application resulted in large crystals forming in the

matrix glaze.

The design is created by adhering a mask and then applying the main

glaze. After drying, the mask is removed

150 deg F an hour to 250 deg F

400 deg F an hour to 1800 deg F

300 deg F an hour to 2050 deg F

120 deg F an hour to 2310 deg F with a hold of 20 minutes at 2310 deg F

300 deg F an hour to 1750 deg F then a half hour hold at 1750 deg F

300 deg F an hour to 1700 deg F then a Three hour hold at 1700 deg F

25 deg F an hour to 1650 deg F then a one hour hold at 1650 deg F

K2O 0.1

Al2O3 0.59

SiO2 3.14

molecular percent Silica 63%

K2O .09

Al2O3 .43

SiO2 2.7

molecular percent Silica 65%

Added:

1% Cobalt Carbonate

.67% Copper Carbonate

As easter egg dye spreads by diffusion into the entire pot, the higher

concentration of CaO

Most of the increase in area covered by the inlay is attributable to crystal

growth in the matrix (background) glaze,

The mask for the inlay is a simple wiggly line. After firing, the inlay is

considerably broadened.

The closeup images were enhanced to increase the visibility of the crystals.

The yellow seen in

by no more than an eighth of an inch

before firing, with no overlap whatever for large parts of the design.

The original mask for the inlay was a curved line, a scribble,

and nowhere more than

half an inch across.

is high in alkaline earths, particularly CaO, and lower in alumina.

and the open area filled in with a

second glaze, using a bulb syringe.

Close up Images of the interaction region

Image of the piece

bowl with glaze satIron_ZG_0 and inlay alexanderBowl_0_Z1Y

bowl is ~9 inches in diameter

oxidation firing to cone 10 in an electric kiln

Firing profiles

Up Fire profile

Down Fire Profile

Clay body is a grolleg porcelain from Tacoma Clay Art Center.

glaze compositions

Background glaze

Empirical Formula satIron_ZG_0 :

Na2O 0.49

Li2O 0.19

CaO 0.16

MgO 0.06

Fe2O3 0.20

P2O5 0.04

Inlay Glaze

alexanderBowl_0_Z1Y :

Na2O .05

CaO .70

MgO .16

Remarks

Metallic micro-crystals appear in this glaze if applied thickly. Here we

see acicular crystals growing

in the interfacial region distinct from its

native metallic micro-crystals. These acicular crystals are reminiscent

of

those seen in the glaze

satIron_Ip7_5

in the inlay glaze will migrate into the matrix,

encouraging the creation of an additional crystalline phase

in the matrix

glaze.

and diffusion of the inlay glaze into

the matrix.

the inlay is the strong primary yellow as seen.